In the beverage and pharmacy industry, the safe, efficient transportation of glass containers is a critical challenge. Given the fragility of glass, it is vital to implement solutions that minimize damage risk and ensure precise movement along the production line. Timing belts with dual coatings—using foam as an intermediate layer—provide an innovative and highly effective approach for this need.

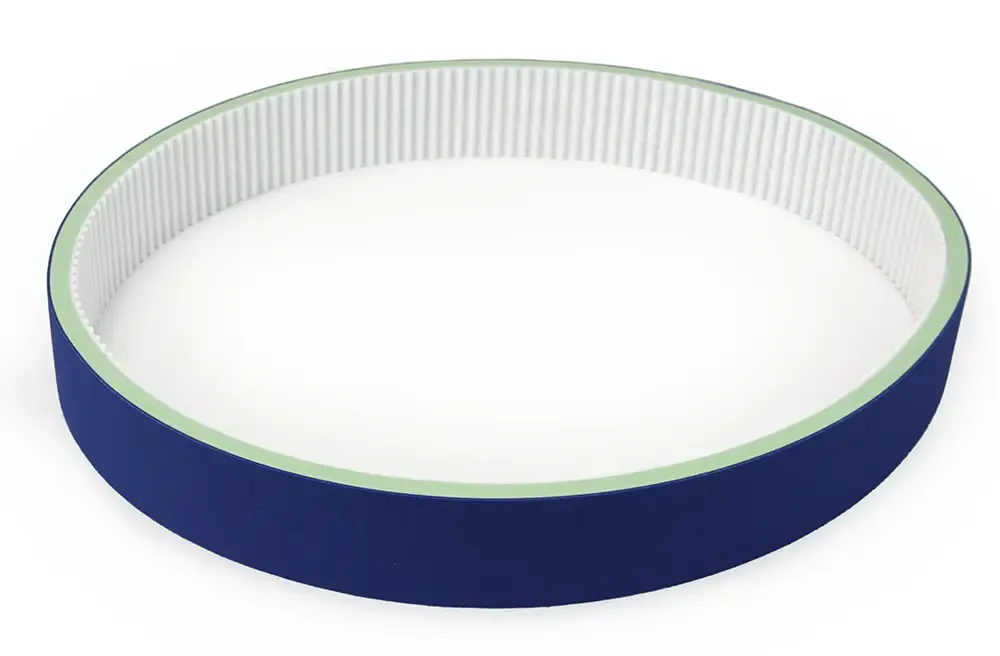

These belts combine materials in a strategic stack-up. The foam, placed between the timing belt and the top coating, acts as a shock absorber, damping impacts and vibrations. Importantly, the surface in direct contact with the containers is not the foam itself, but a purpose-selected coating tailored to each application. This outer coating delivers the right balance between grip and controlled slip, enabling stable transport of glass containers without excessive friction that could compromise integrity.

Ydins supplies customized solutions in this area, allowing the selection of both the surface coating and the foam density to match different operating conditions. Available coatings include options with FDA-compliant (food-grade) properties, anti-slip, non-stick, and high-temperature resistance, each engineered to optimize the safe handling of glass bottles and jars.

The use of these belts is especially advantageous at critical points such as inspection and filling stations. In these stages, bottles must maintain a stable, controlled position, avoiding abrupt movements that could affect filling accuracy or defect detection. With the appropriate surface coating, timing belts ensure smooth, uninterrupted, and repeatable motion.

Beyond improving transportation safety, these belts help extend equipment life by reducing mechanical wear and limiting residue build-up on the contact surface. The combination of shock-absorbing foam with a specialized coating not only protects glass containers but also boosts overall production efficiency.

In conclusion, timing belts with dual coatings are an advanced solution for glass handling in the beverage and pharmacy packaging sector. Their customized design and blend of high-performance materials enable safe, efficient, and low-risk transportation, preserving final product quality while optimizing production line performance.