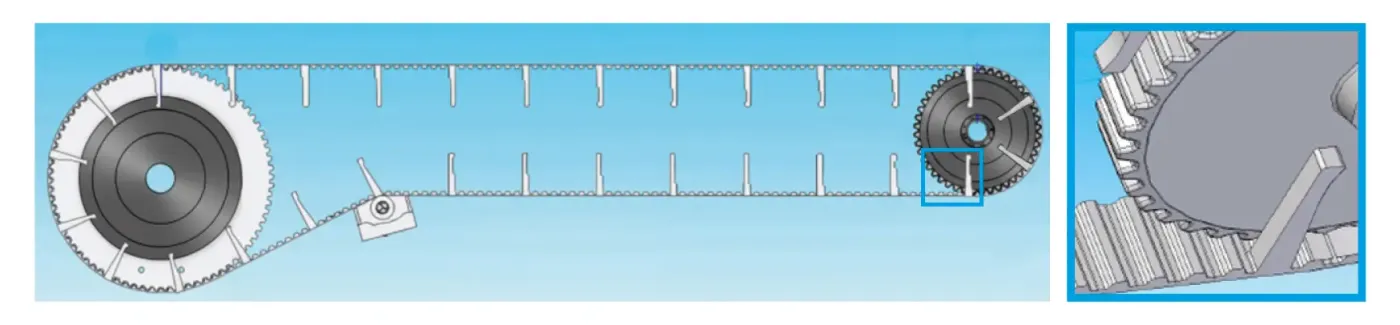

At Ydins we develop transport solutions adapted to the most demanding needs of the industry. An example of our innovation are the custom-made belts with cleats on the toothed side, a design specially conceived for the transport of coins in self-checkout stations.

The complexity of transporting coins on machinery that processes cash

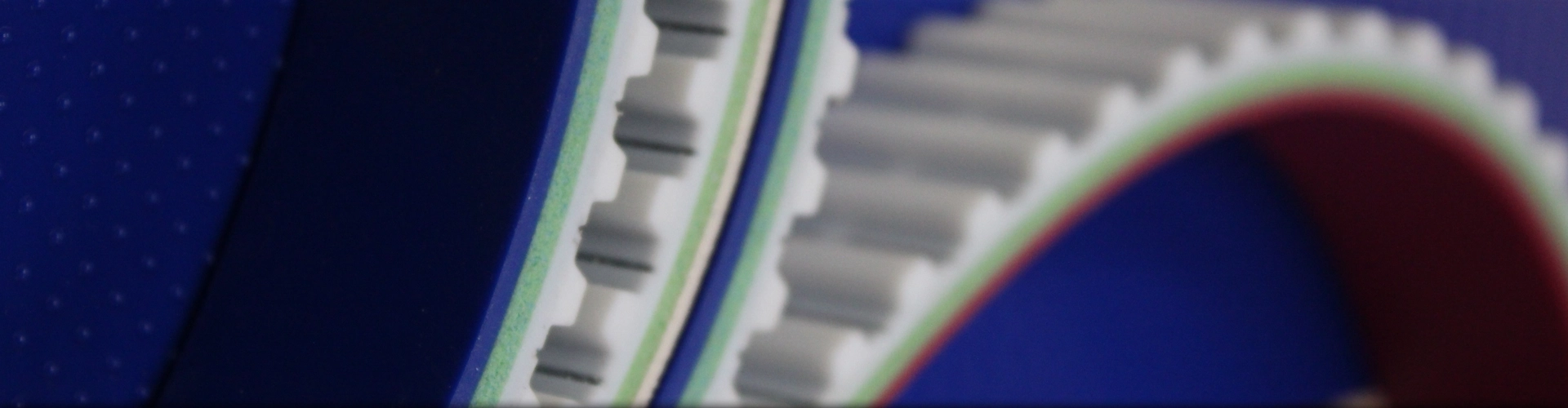

Automatic payment stations and other cash handling equipment demand pinpoint accuracy to move each coin without jamming or misalignment. The available space is limited, the turning radii on pulleys are critical and the tolerances of the system allow for hardly any deviations. For this reason, the effective solution involves a tailor-made design of the conveyor belt and, in this case, working directly with the technical department facilitates the processes to reach the most suitable solution.

The Ydins solution: patented cleats

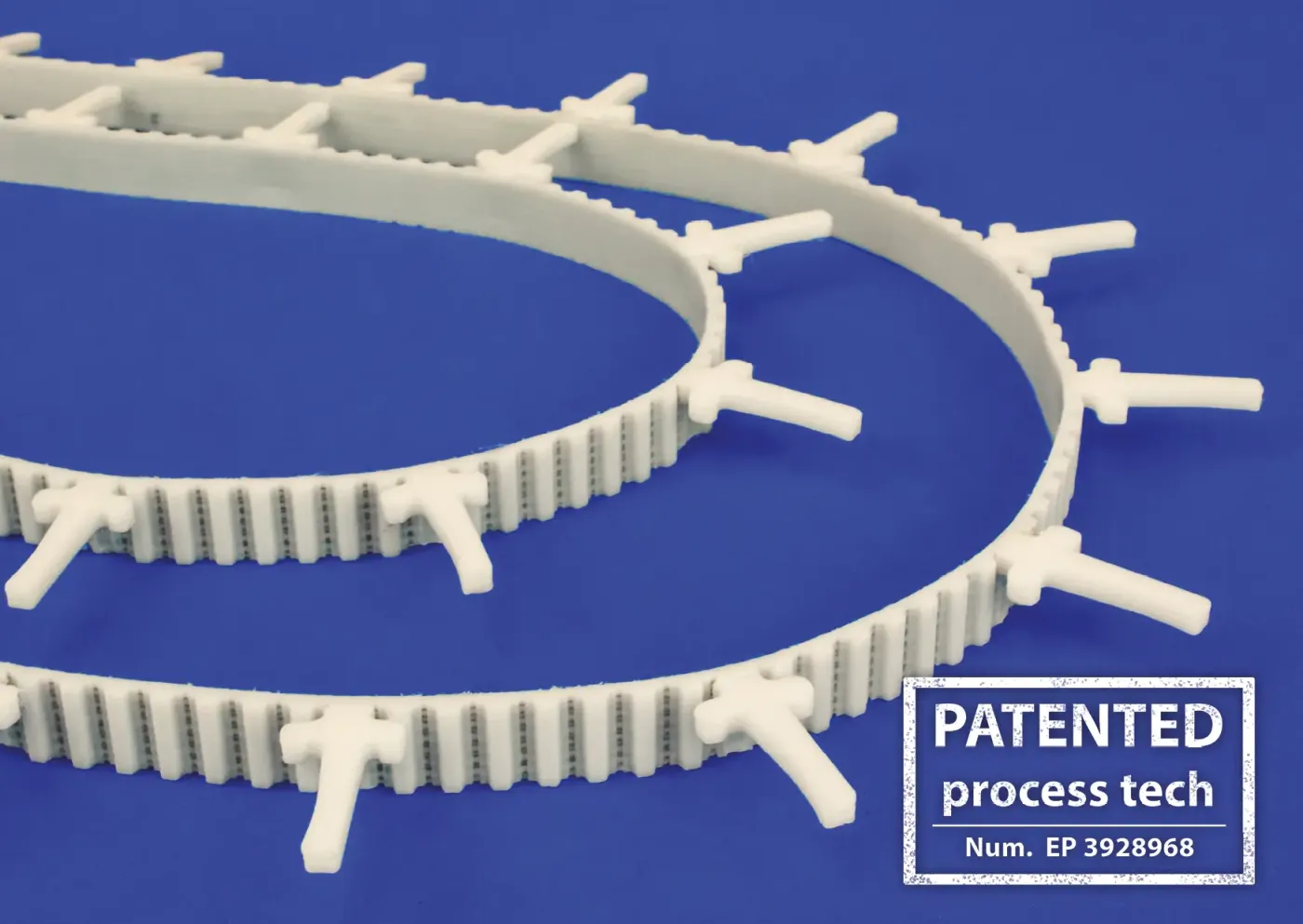

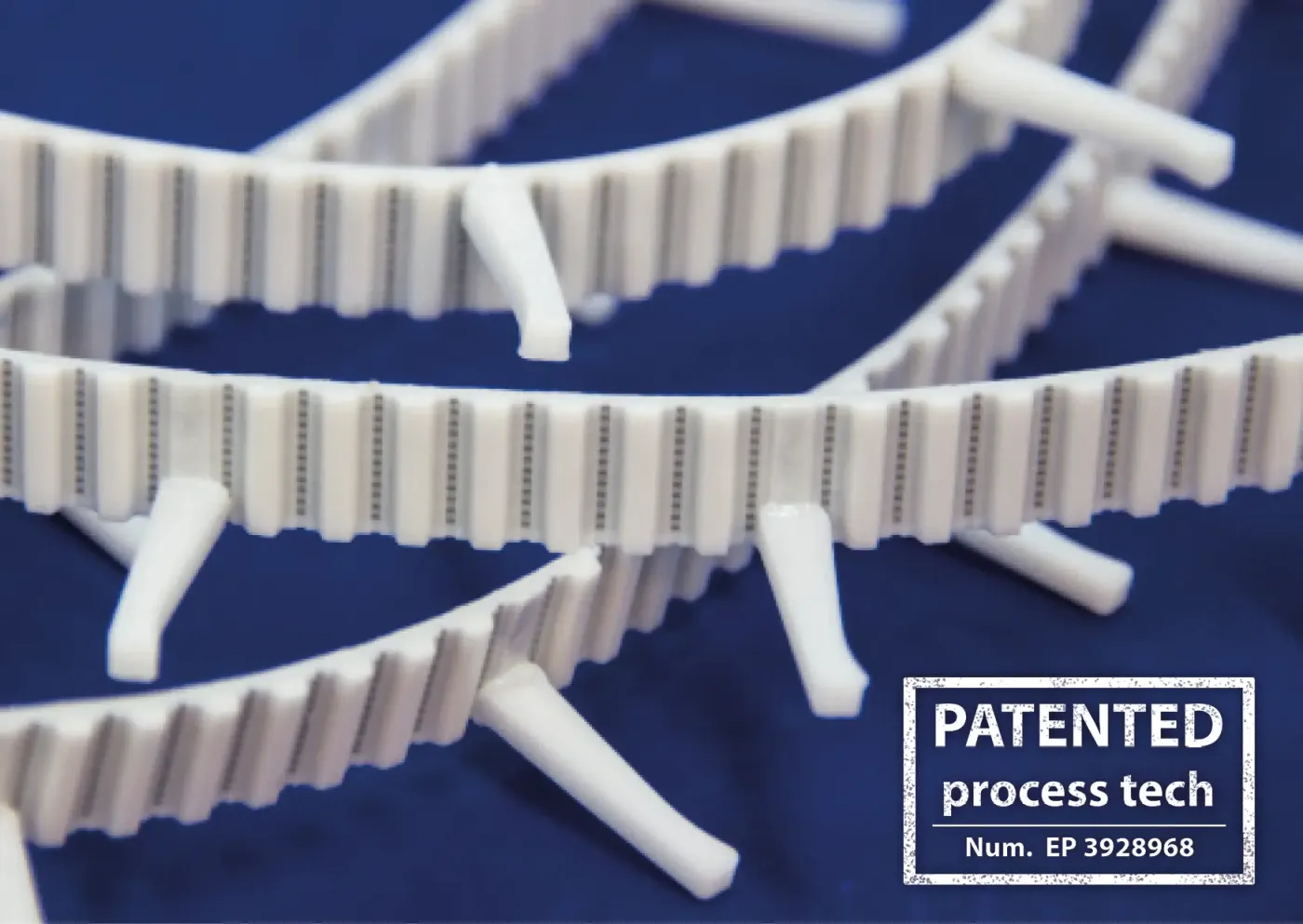

Ydins manufactures custom-made cleat belts, adjusting to specific applications such as coin transport. In this case, the cleats are inserted into the toothed side of the belt and have been designed to capture, guide and release the coin in each phase of the journey, maintaining the continuity of the service.

Tailored dowels that improve processes

On many automated lines, the success of the transport depends on how the dowel captures, guides and releases each unit. Standard guide structures rarely fit with dimensions, turning radii, inclinations, or friction.

Designing the custom cleat and validating the solution with a technical team that knows the process is the most reliable option to control the efficiency of machinery of different types:

- Cash Management

- Car park

- Vending

- Ticketing

- Part Sorting

- Automotive

- Pharmaceutical/Cosmetic

- Recycling

Ydins Technical Office: advice to get it right the first time

Our team accompanies the project from the beginning to define the geometry of the cleat, the pitch, the belt width and the minimum working radius depending on the machine and the coin flow. This direct advice reduces iterations, accelerates validation, and delivers a successful, production-ready final solution.

Thanks to direct advice, we take into account the end use of the strap and adjust to the needs in aspects such as:

- Exact belt and cleat structure and dimensions

- Hardness and stiffness according to type of product to be transported

- Choice of cue color to improve your visibility on the line of work

- Plug welded to the belt

- Plug screwed to the belt

- Interchangeable cleat option

Do you need a belt with cleats that improves your transport processes?

Contact our Ydins technical team and we will help you find the ideal solution.