In the food industry it is not always easy to ensure traction and conveying efficiency while also meeting food-contact regulations. Lines work with slopes, humidity, greases and temperature changes, and many easy-to-clean coverings do not offer enough traction, while others with good grip are not approved for direct food contact.

YDINS solves this balance with a belt that does not force a choice between hygiene and performance.

A single belt that combines food safety and effective traction

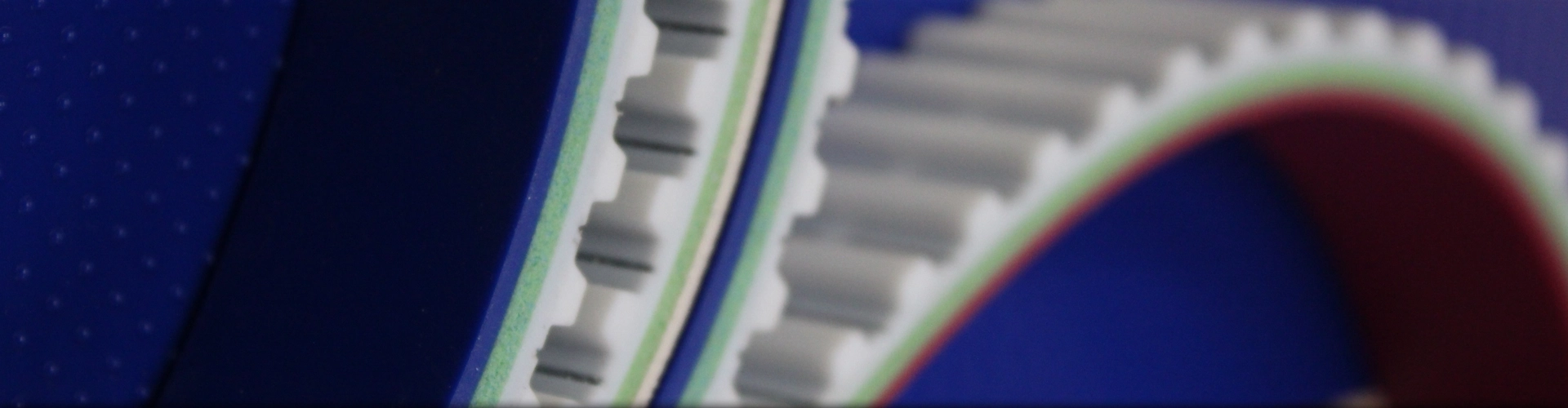

With YDINS we provide the 100% FDA combination for food conveying: a PU timing belt and Fishbone (herringbone) coating; both materials comply with food-safety regulations.

YDINS manufactures custom timing belts for direct food contact. The Fishbone finish is especially designed for meat lines (deboning, slicing, packing). The positive drive of the toothed base combines with the high traction of this covering to stabilize the product in wet or greasy areas.

Benefits from the first day of production

- Safe food contact: FDA-compliant materials suitable for both raw and processed meat.

- Fewer slips and losses: the Fishbone coating provides stable grip with water, brines or fats, even on inclined lines.

- Made-to-measure integration: YDINS adapts width, length, joints and offers machining of the covering, including FDA cleats and guides embedded into your belt.

- Operating temperature range: –10 °C to 70 °C, adapting to different processes on the line without damage.

Drainage and cleaning without compromising grip

The design of the Fishbone finish favors drainage of liquids and residues, reduces retention points and speeds up cleaning, helping to minimize cross-contamination while maintaining the coefficient of friction needed for conveying on slopes.

Other FDA finishes

If your product needs a different grip requirement, in addition to Fishbone YDINS supplies other FDA-compliant finishes to tune traction according to food type, gradient, humidity and cleaning protocol. This ensures the right grip for each process without compromising hygiene or durability.

- Smooth coatings

- Rough coatings

- Stud/pin (buttons) coatings

- Transverse or longitudinal groove coatings

- Sawtooth-finish coatings

Shall we prepare an FDA made-to-measure proposal for your line?

Contact our office and together we will find the solution that best fits your production line.