Custom-made Belts

Ydins belts are custom-designed to ensure optimal performance in any environment.

Our expertise in manufacturing and customization allows us to develop solutions tailored to every need.

We work with high-performance materials and advanced technology to produce timing belts with specific characteristics according to the sector and application.

Our commitment to personalized service, quality, and innovation enables us to offer synchronous belts that ensure reliability, high performance, and seamless integration into production processes.

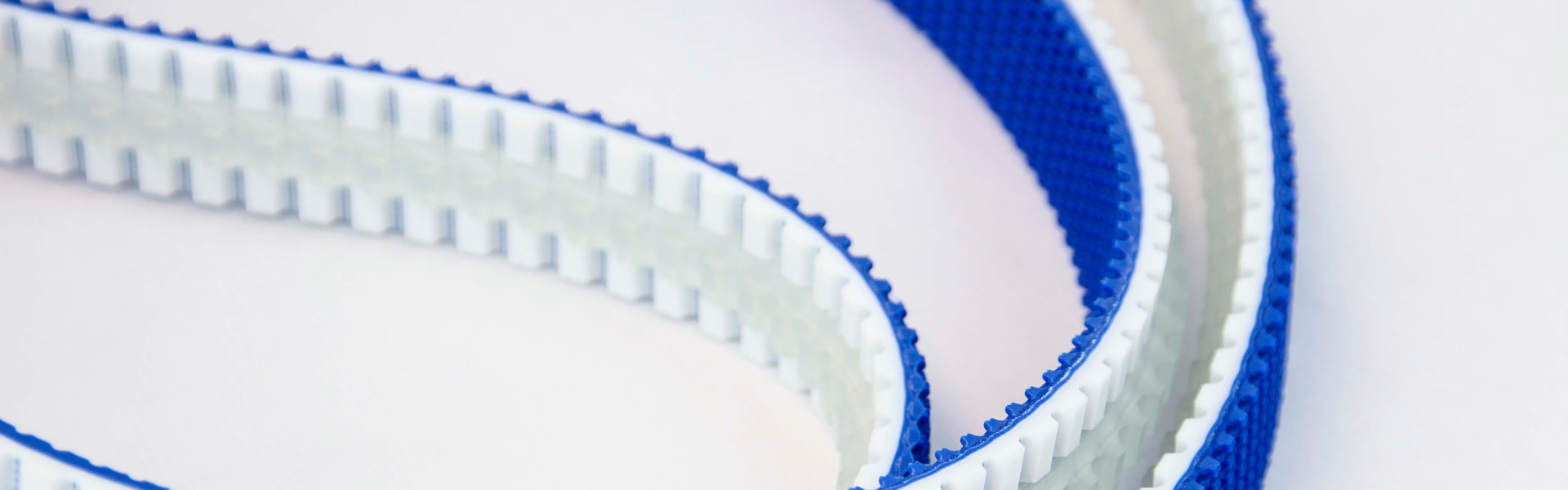

Coated belts

Coatings on timing belts are a solution to improve the performance, adaptability and safety of transportation systems indifferent industrial sectors. Each coating has specific properties that meet the demands of each application, ensuring efficient and safe operation.

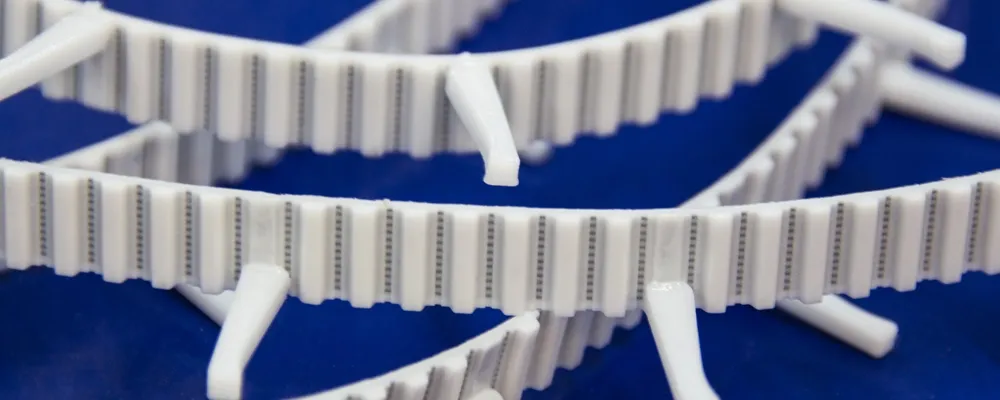

Learn moreBelts with custom cleats

One of the elements that enhances the functionality and versatility of timing belts in the industrial sector is custom cleats, which optimize product transportation by providing greater stability and facilitating transport in many types of systems.

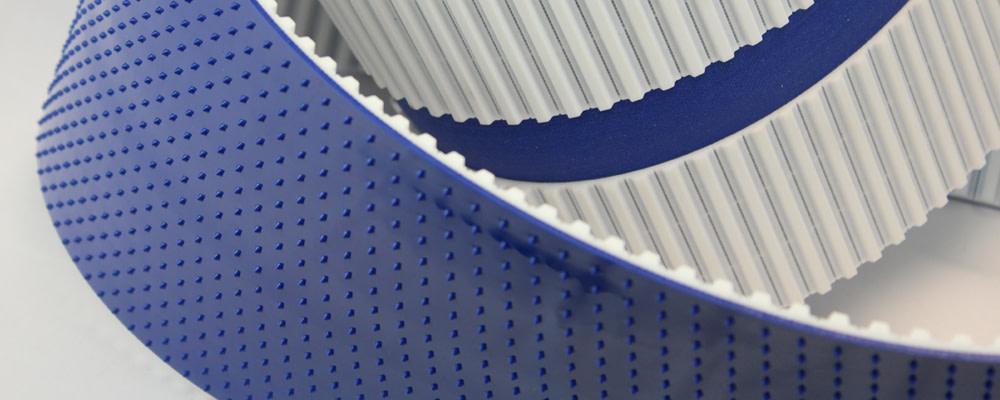

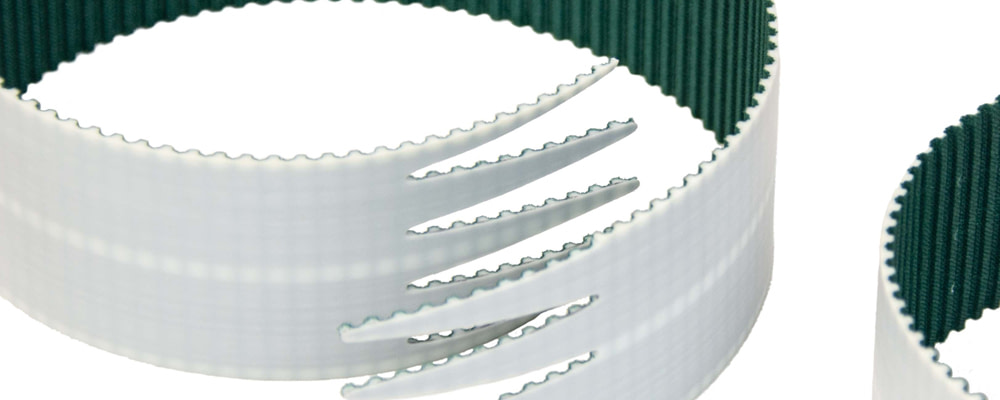

Learn moreSpecial machined belts

Special machining on timing belts ensures optimal performance and meets the specific demands of each application. Every sector and process has unique requirements, and customization allows the belt’s features to be tailored to particular working conditions. This results in significant improvements in the efficiency, safety, and durability of the conveyor system.

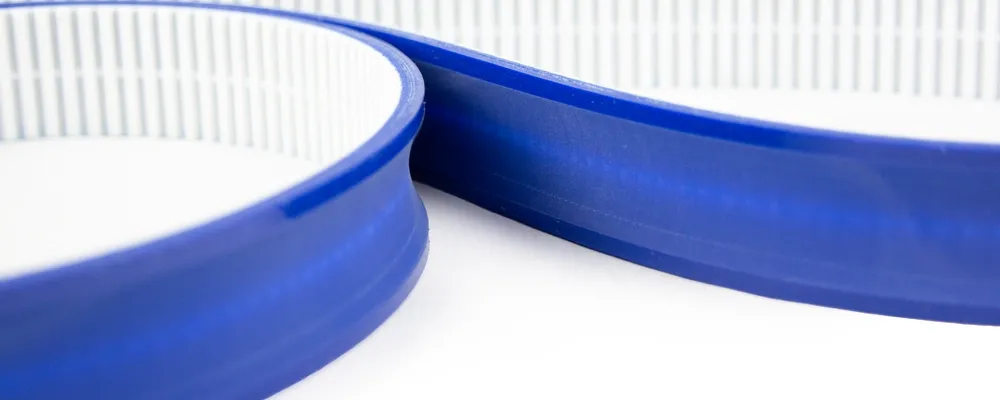

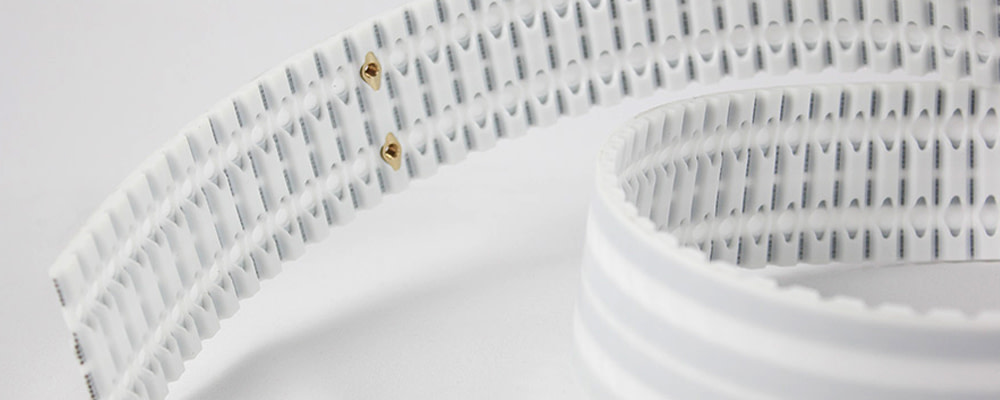

Learn moreBelts with inserts & false teeth

In industrial transport systems, inserts and false teeth in timing belts are components that ensure a firm attachment of cleats while maintaining the integrity and functionality of the belt’s toothed base. These elements guarantee stable and efficient transportation, adapting to the specific needs of each process.

Learn moreJoining methods for belts

In the industrial sector, timing belts are a essential component for the efficient transport of materials. The joining of these belts is key to ensure operational continuity and minimize downtime. The three most prominent joining methods are:

- Pin-Joint

- Hooks

- Welded