Joining methods for belts

In the industrial sector, timing belts are a essential component for the efficient transport of materials. The joining of these belts is key to ensure operational continuity and minimize downtime.

The three most prominent joining methods are: Pin-Joint, Fasteners, and Endless.

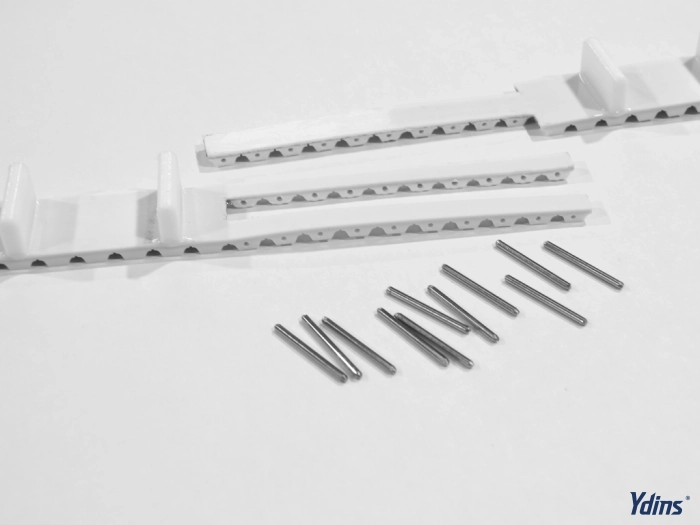

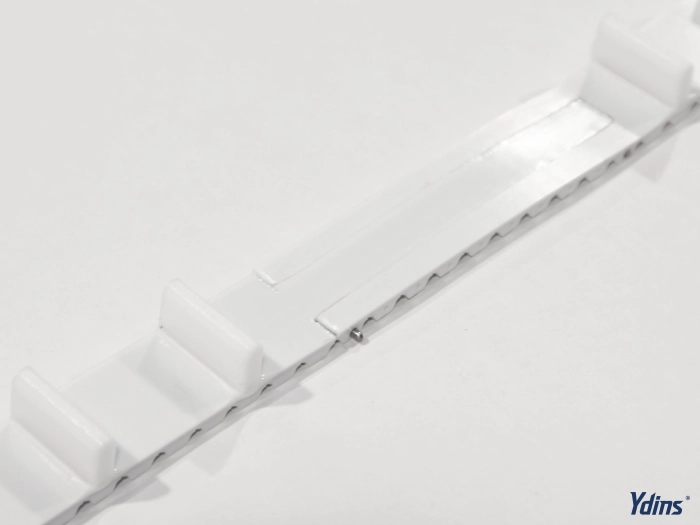

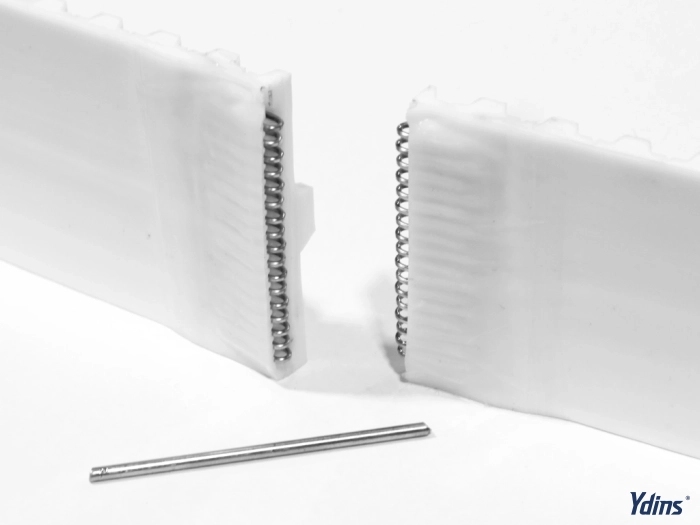

PIN-JOINT

The Pin-Joint is a method that enables quick and easy belt connection by using a pin inserted into the pre-drilled ends of the belt. This type of splice is ideal for applications requiring frequent assembly and disassembly.

FEATURES

- Quick installation and removal.

- Requires prior belt preparation with precise perforations.

- Provides a solid connection.

ADVANTAGES

- Easy maintenance and pin replacement.

- Does not require complex tools.

- Ideal for environments where quick belt changes are needed.

APPLICATIONS

- Sorting and packaging systems.

- Modular conveyors.

- Food and pharmaceutical industries where quick disassembly for cleaning is crucial.

HOOKS

This joining system is a mechanical method that uses metal hooks to join the ends of a belt. It is one of the most common methods due to its simplicity and effectiveness under various conditions.

FEATURES

- Quick and easy installation.

- Use of metal hooks that provide a robust connection.

- Applicable to belts made of various materials.

ADVANTAGES

- Strength and durability under demanding working conditions.

- Easy to install without the need for specialized equipment.

- Suitable for emergency repairs.

APPLICATIONS

- Mining and construction.

- Agriculture.

- Food processing.

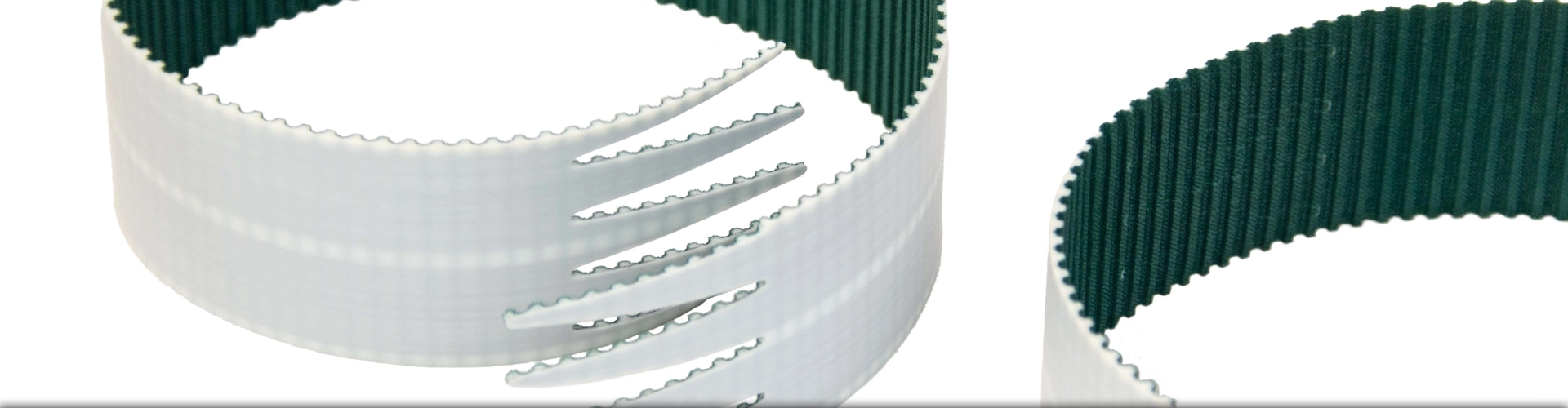

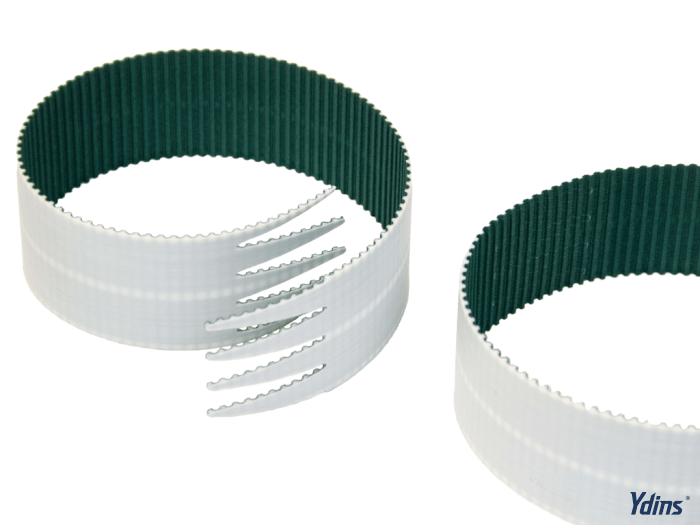

WELDED

The welding system allows for a continuous and permanent connection of belts without the need for mechanical splices. This method is ideal for applications requiring a strong and durable connection.

FEATURES

- Continuous connection in the belt without interruptions.

- Does not require perforations or additional components.

- Increases strength by eliminating stress points.

ADVANTAGES

- Greater durability due to the absence of mechanical joints.

- Ideal for applications requiring continuous transmission.

APPLICATIONS

- High-load conveyors in heavy industries.

- Equipment where constant transmission is essential.

- Sectors such as automotive or textile, minimizing the risk of breakdowns.

Discover our catalog

of belt jointing systems.

DOWNLOAD PDF