Choosing the right timing belt is a decisive step in any industrial process. It’s not only about transferring a product from A to B, but doing it with efficiency, reliability, and full adaptation to the working environment. Every parameter counts: the type of material, environmental conditions, load capacity, and hygiene requirements determine which belt is the best fit for each application.

In many scenarios, standard belts fall short of all system demands. That’s where a custom-made belt truly stands out. A belt conceived and produced specifically for your requirements ensures optimal performance, aligning precisely with every stage of the process.

When to Choose a Custom-Made Belt

Across numerous industrial operations, standard timing belts are not sufficient to address the unique needs of the system. Each application poses distinct challenges: from extreme environmental conditions to intricate mechanical layouts, including high precision or seamless integration with auxiliary equipment. In these situations, a custom belt not only guarantees safe and efficient operation, but also enhances system longevity and can significantly reduce life-cycle costs. Opting for a tailored solution means tuning every detail to the real demands of the process, thereby optimising overall line performance.

A custom-made belt is particularly advisable in the following cases:

- Processes with complex geometries or special requirements.

- Environments with demanding conditions (temperature, humidity, chemical agents, hygiene, etc.).

- Integration with automated systems requiring precision.

- Need to enhance performance and reduce downtime.

Advantages of choosing Ydins custom belts

Ydins applies a technical, personalised approach to every project, delivering solutions tailored to each application. Key benefits include:

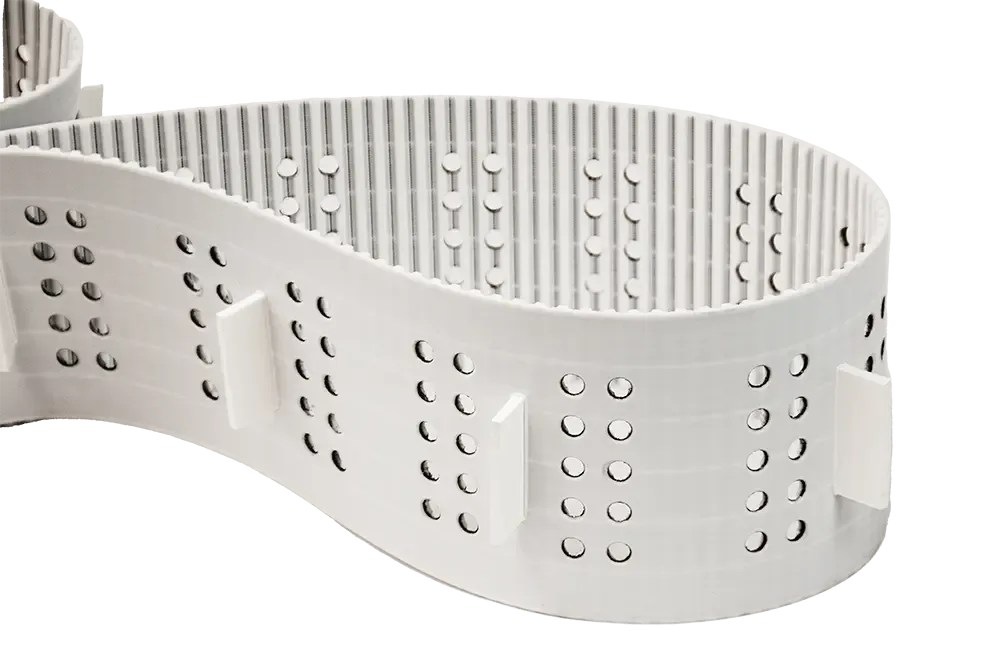

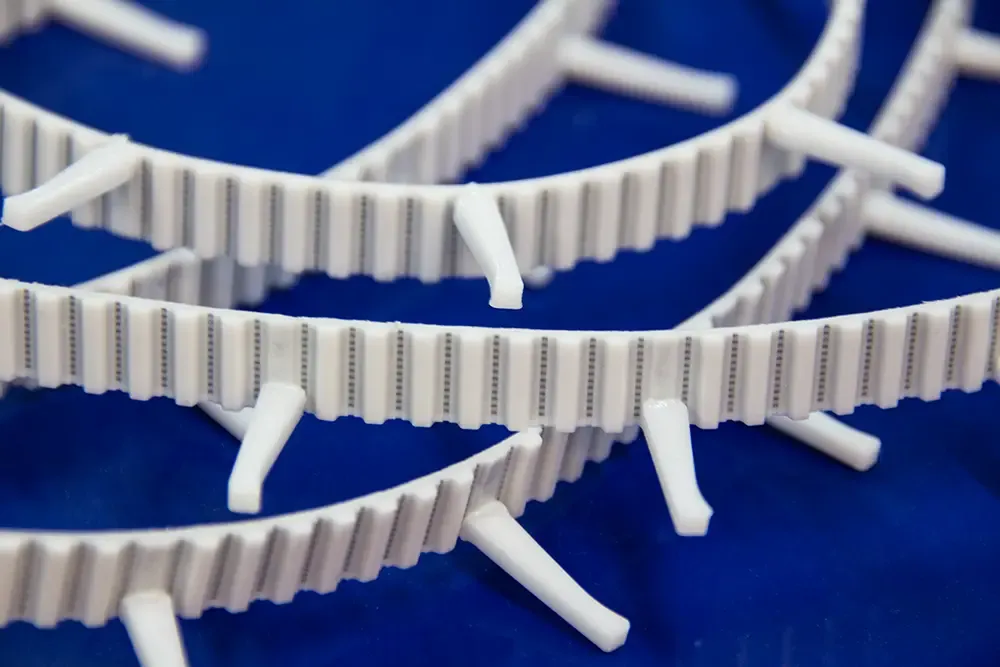

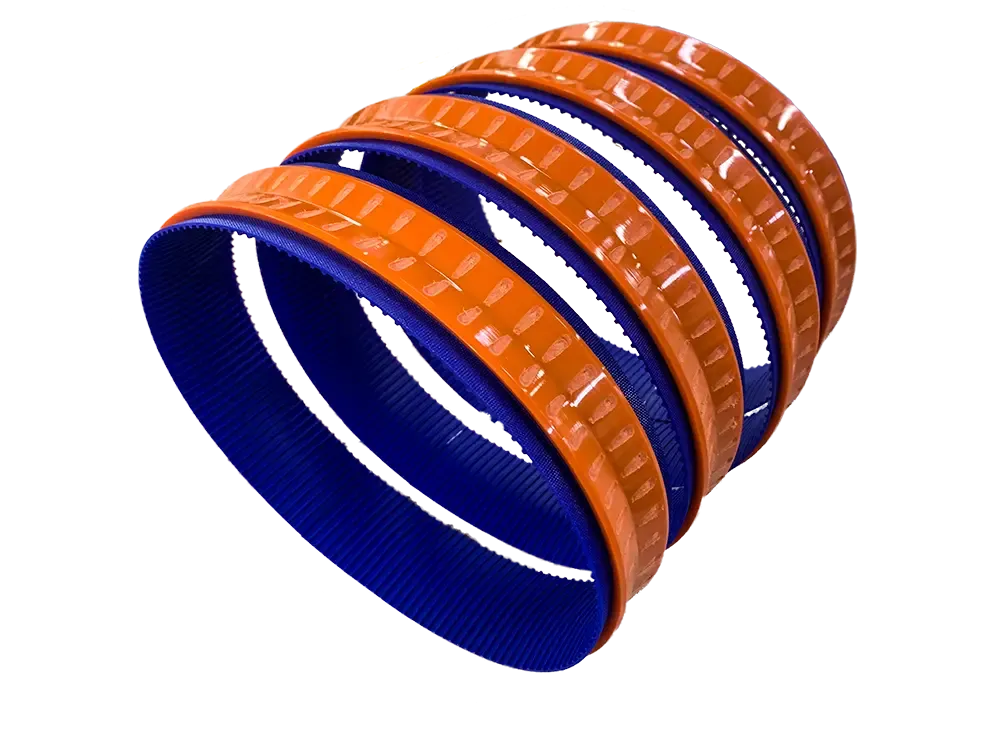

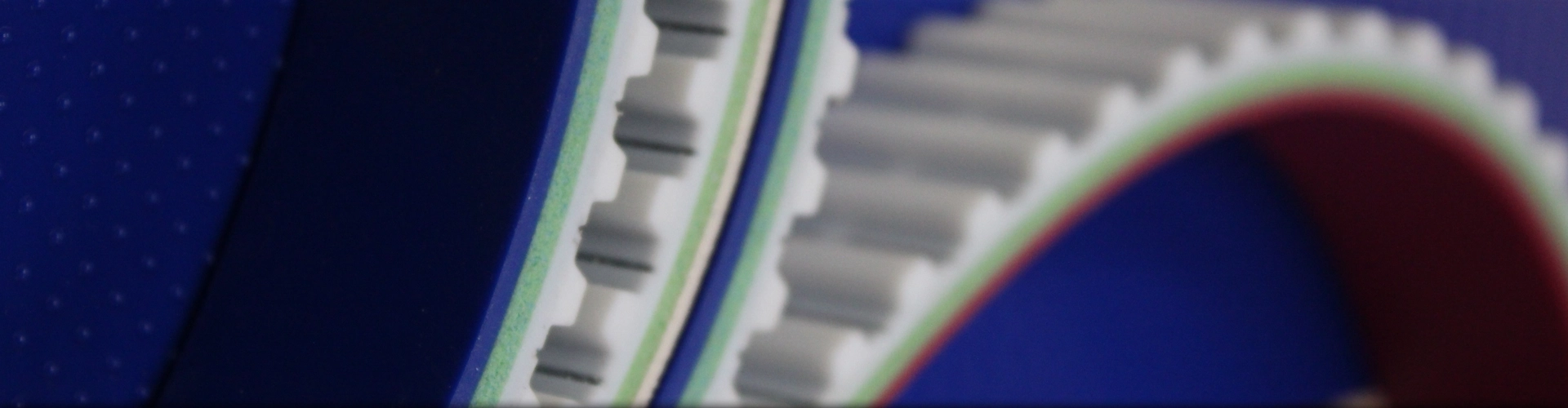

- Customised design: expert guidance to configure the ideal timing belt (cleats, guides, coatings, machining, etc.).

- Precision manufacturing and high-performance materials, validated through rigorous quality testing.

- Adaptation to multiple sectors: food & beverage, pharmaceutical, automation, logistics, packaging, ceramics, and more.

- Greater durability and simplified maintenance thanks to performance-oriented engineering.

- Specialised technical support from the design phase through commissioning.

A custom-made timing belt doesn’t just fit the process—it optimises the process. If your application demands reliability, precision, strength, or full integration, Ydins custom belts are the right choice. Don’t settle for a generic timing belt; choose a solution engineered for you.