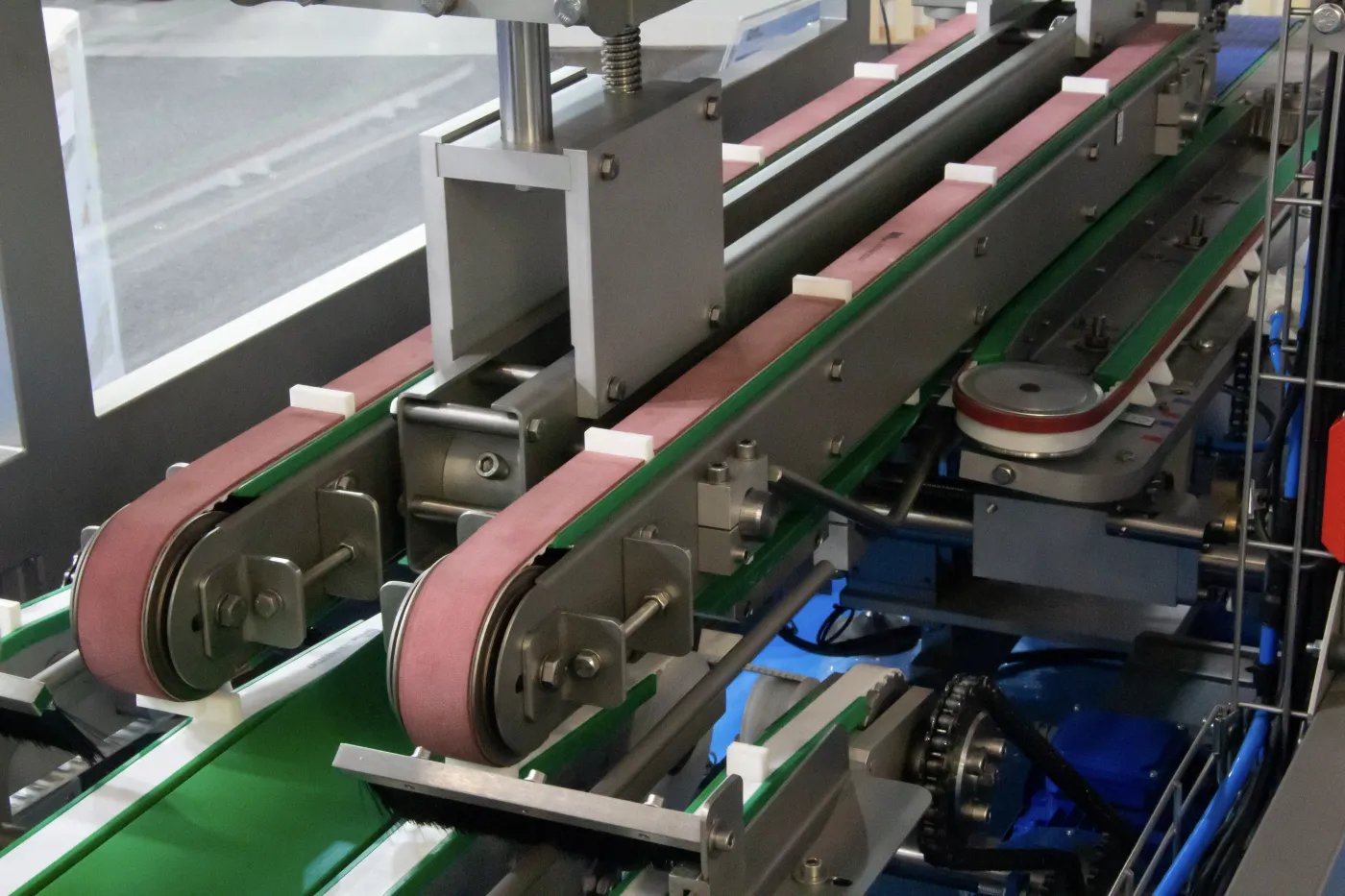

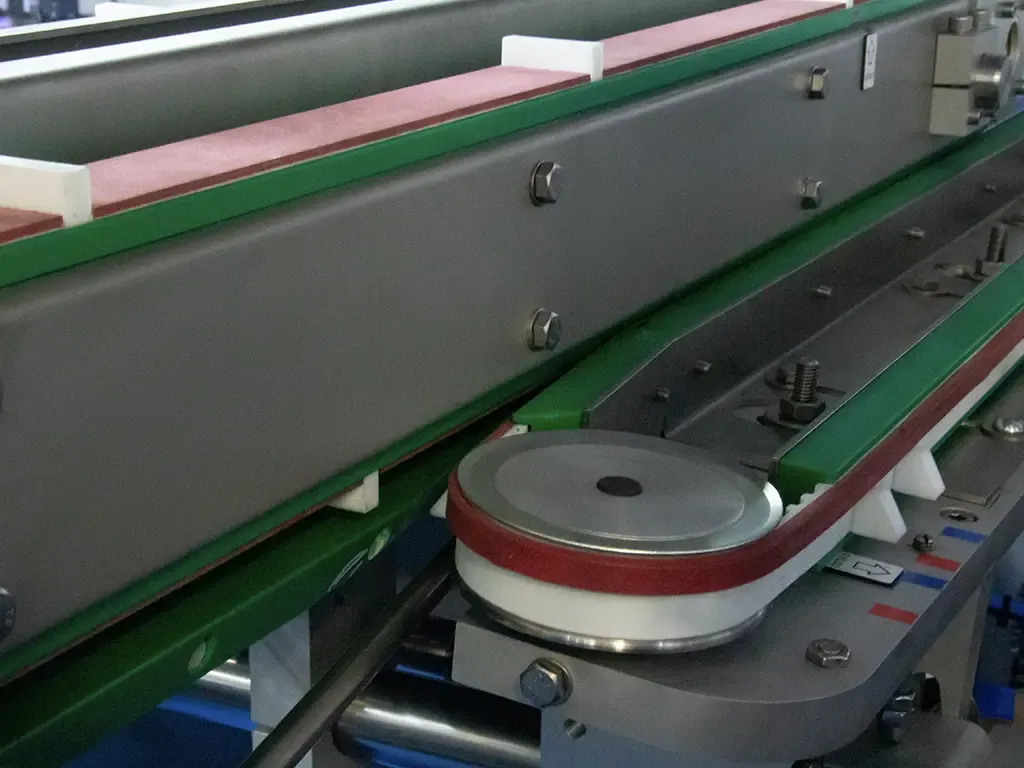

YDINS custom timing belts for packaging processes: a key element in production efficiency

In the packaging industry, lines must run fast, accurately, and with the flexibility to handle a wide range of products. In this scenario, custom-made conveyor belts have become essential to secure efficiency, safety, and reliability across the entire packaging process.

Why custom timing belts are the best choice for packaging

Packaging operations move products that vary in shape, weight, texture, and hygiene requirements. Relying on standard belts in this context introduces limitations that directly affect line efficiency. For example:

- Transporting unstable products: without the proper grip, items can slip or shift, compromising correct packaging.

- Synchronization issues: if the belt is not properly adapted, products won’t reach each machine (dosing, labeling, etc.) at the right moment, causing errors.

- Frequent stoppages: an unsuitable belt can fail or lose alignment, forcing the line to halt for corrective actions.

Ydins custom belts, by contrast, are engineered considering all critical process variables—product type, line speed, environmental conditions, and integration with other equipment—ensuring more precise and reliable transport.

Key customizable elements for packaging lines

- Technical coatings

In packaging, the belt must deliver the right level of adhesion for each product. Specific coatings are applied to prevent containers from slipping or sticking—even when wet, hot, or with product residues—maintaining control without damaging surfaces.

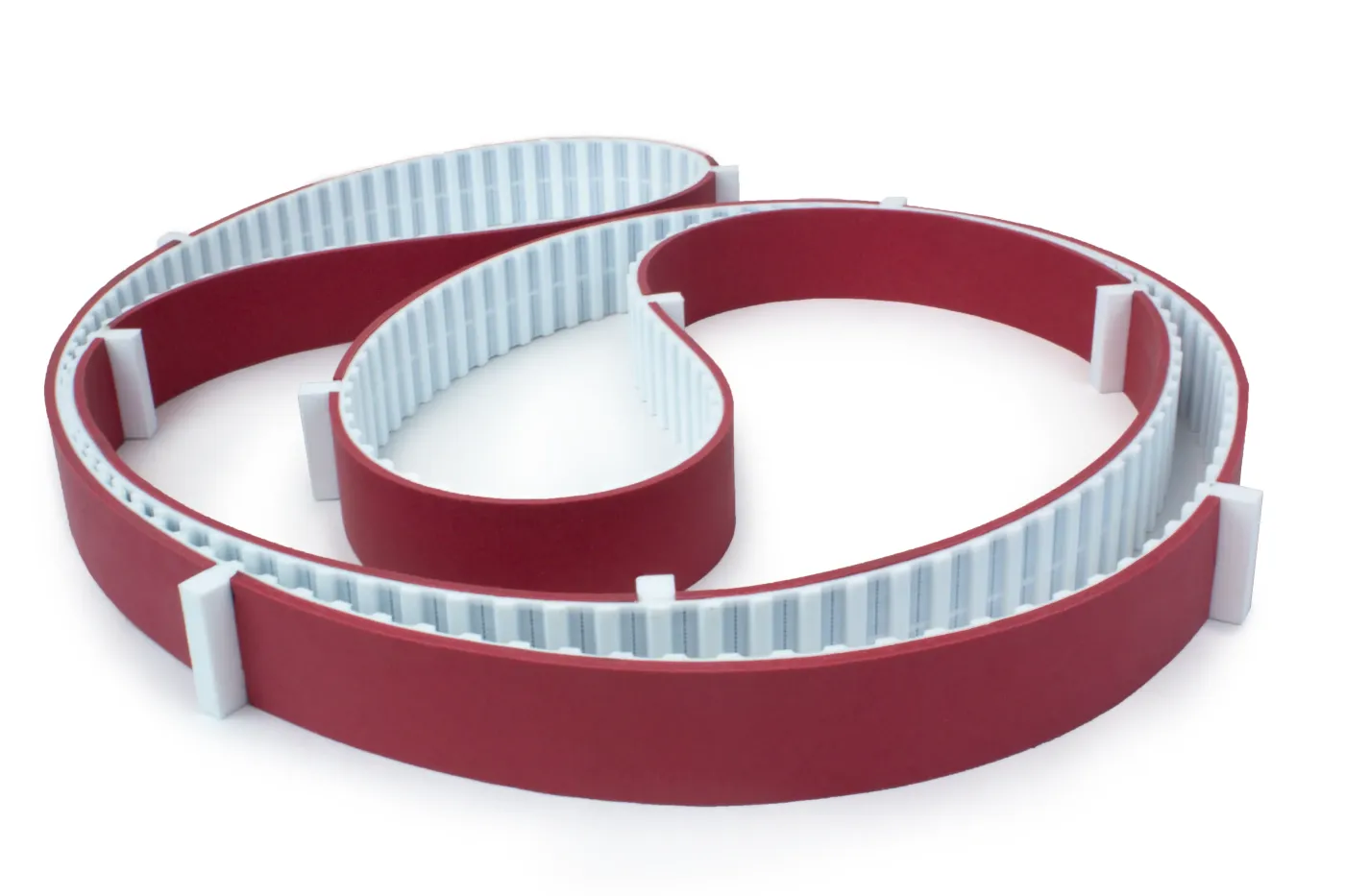

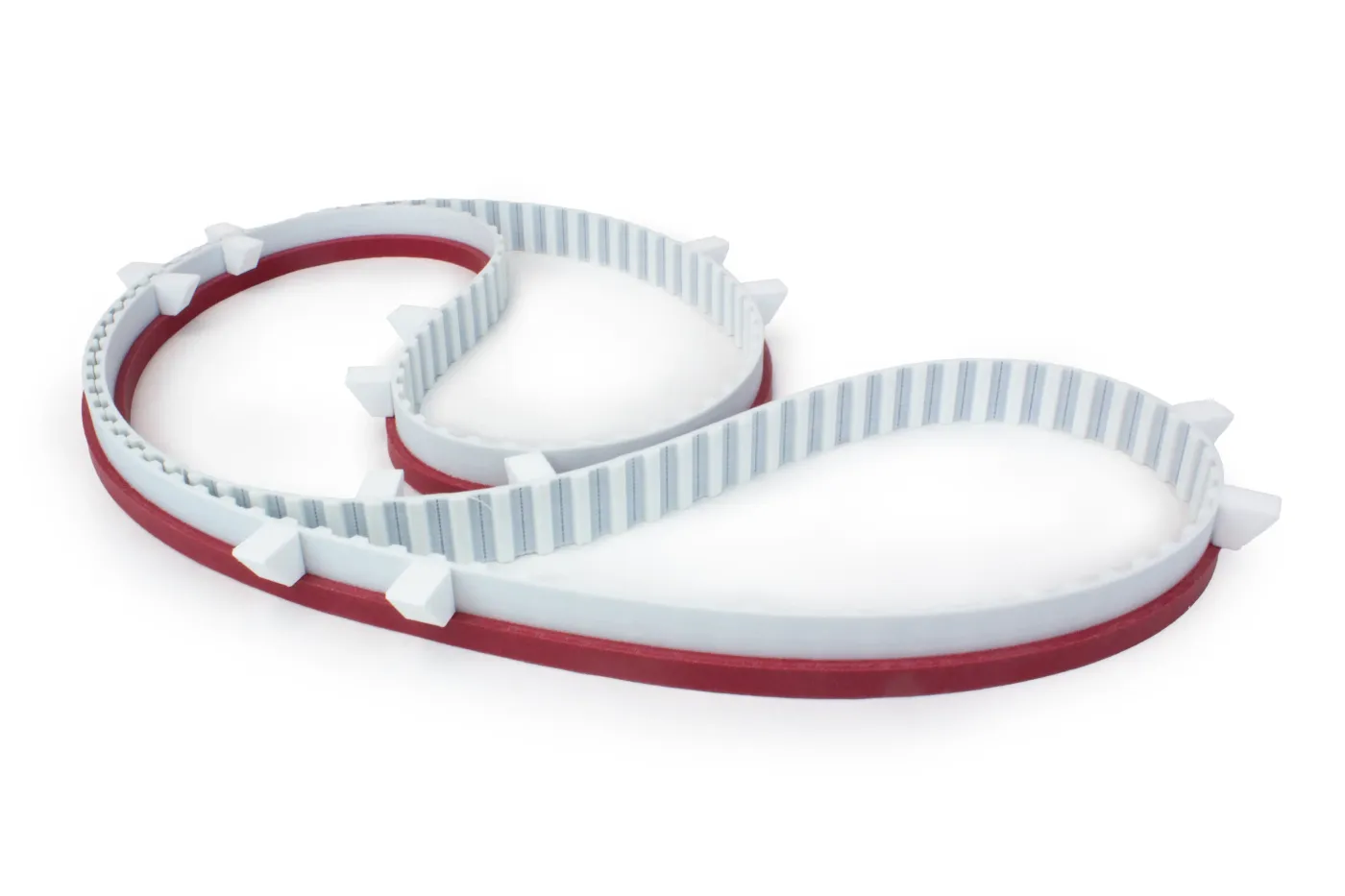

- Cleats and profiles

Studs and profiles are particularly useful where precise product movement, incline conveying, or spacing is required. Their geometry, size, and placement are tailored to the container type to ensure secure traction without harming contents.

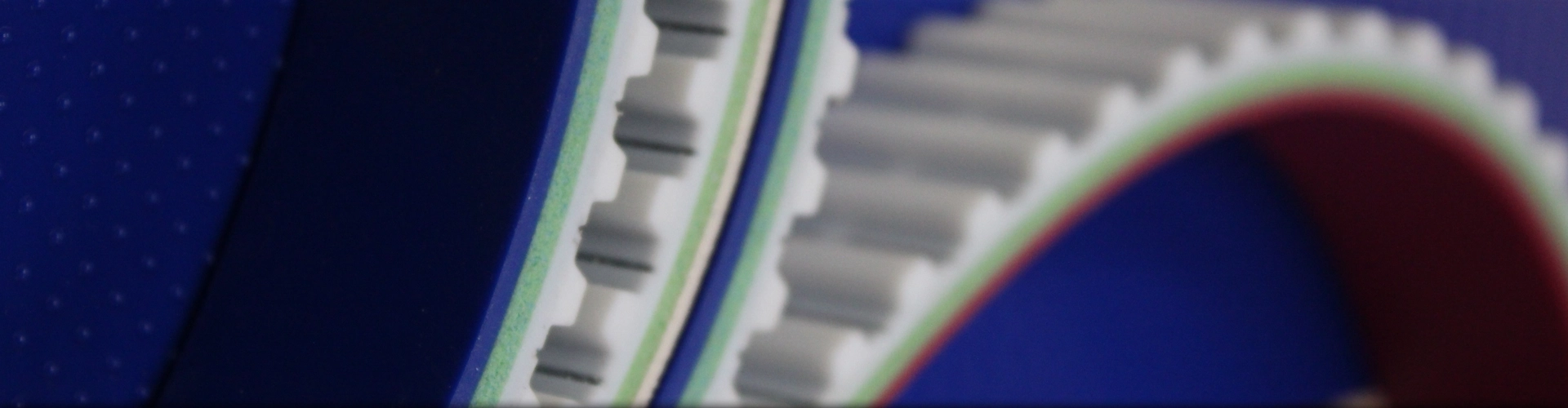

- Custom machining

Belts can incorporate perforations, grooves, or slots adapted to positioning, sensing, or vacuum systems. This is crucial for high-precision tasks such as filling, automatic labelling, or sealing, where container stability and alignment are critical.

- Food and pharmaceutical compliance

In food or medical-device packaging lines, belts must comply with regulations such as FDA or EU 1935/2004. Materials are selected for safety, cleanability, and resistance to disinfectants—ensuring hygiene without sacrificing performance.

Direct benefits of customization

- Greater product stability throughout the entire path.

- Reduced waste by avoiding falls, slips, or misalignments.

- Higher production speeds without losing accuracy.

- Lower maintenance, as the belt is optimized for the application from day one.

Adaptation as a competitive advantage

Customizing the belt is not a luxury—it’s essential for optimizing every link in the packaging chain. Each package, product type, and line configuration calls for a specific solution. Choosing custom-made belts from Ydins ensures the right fit for your process while protecting efficiency, reliability, and compliance.