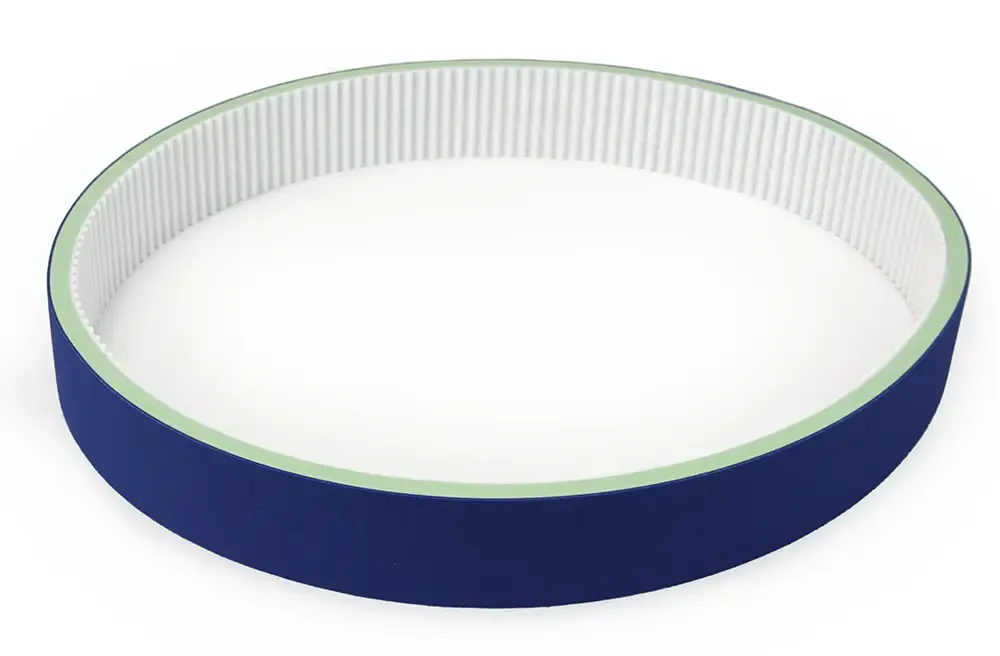

In the beverage and pharmacy industry, the safe and efficient transportation of glass containers is a key challenge. Due to the fragility of these containers, it is essential to employ solutions that minimize the risk of damage and ensure precise movement along the production line. Timing belts with dual coatings, where foam acts as an intermediate layer, offer an innovative and highly effective solution for this purpose.

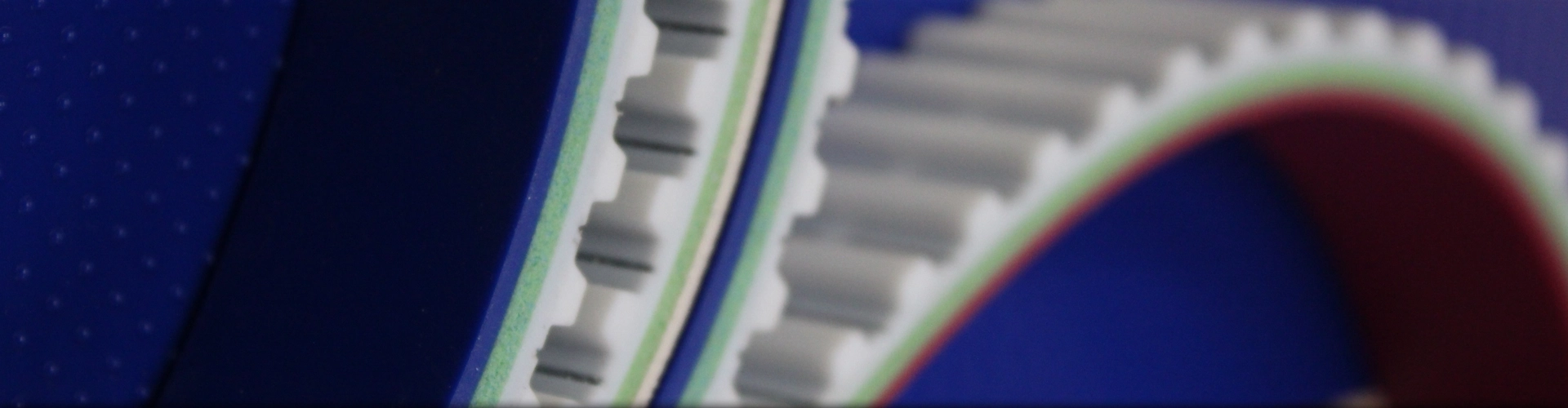

These belts are designed with a combination of strategic materials. The foam, positioned between the timing belt and the surface coating, serves as a shock absorber, reducing impacts and vibrations. However, the surface in direct contact with the containers is not the foam itself but a specially selected coating based on the specific requirements of each application. This surface coating provides an ideal balance between adhesion and controlled sliding, allowing glass containers to be transported stably without generating excessive friction that could compromise their integrity.

Ydins offers customized solutions in this field, allowing for the personalization of both the surface coating material and the density level of the intermediate foam to adapt to different operational conditions. The available coatings include materials with FDA-compliant (food-grade) properties, anti-slip, non-stick, and high-temperature resistance, each designed to optimize the safe transport of glass bottles and jars.

The use of these belts is particularly beneficial in critical applications such as inspection and filling stations. In these processes, it is crucial that the bottles maintain a stable and controlled position, preventing sudden movements that could affect filling precision or defect detection. Thanks to the appropriate surface coating, timing belts ensure smooth and uninterrupted movement.

In addition to improving transportation safety, these belts extend the lifespan of equipment by reducing mechanical wear and minimizing residue buildup on the contact surface. The combination of shock-absorbing foam with a specialized coating not only protects glass containers but also optimizes the efficiency of the production process.

In conclusion, timing belts with dual coatings represent an advanced solution for the glass beverage and pharmacy packaging industry. Their customized design and combination of high-performance materials ensure safe, efficient, and risk-free transportation, preserving the quality of the final product and optimizing production line operations.