In many industrial processes, the transport of materials on inclines presents specific technical challenges: guaranteeing load stability, preventing shifting during movement, and maintaining reliable grip under changing conditions. With cylindrical parts such as tubes, these demands intensify, since their geometry complicates support and clamping on the conveyor surface.

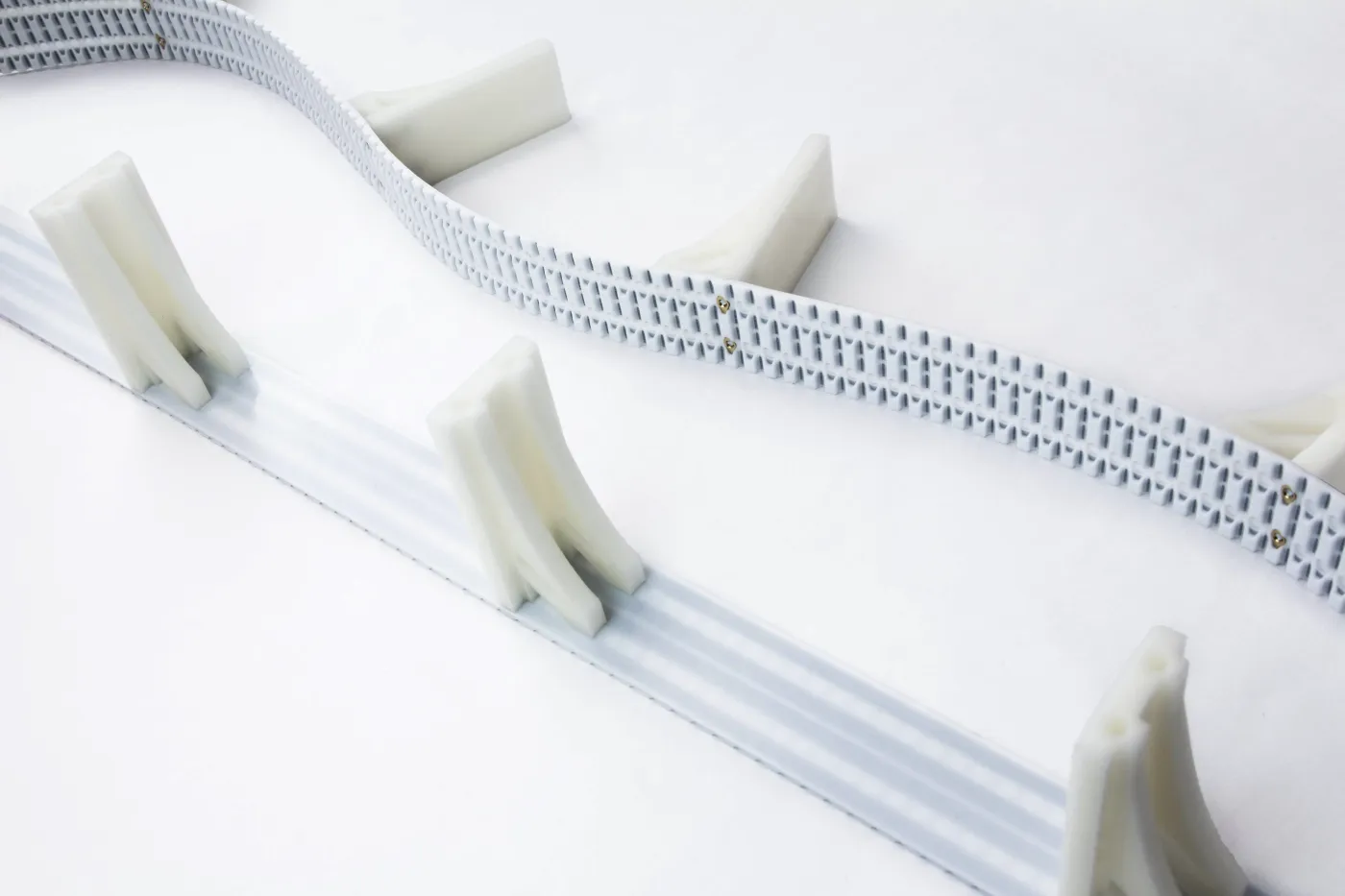

For this type of application, belts with a custom design offer an effective response, as they enable the integration of elements adapted to the product being conveyed. A clear example is the development of a belt with custom cleats by the Ydins brand, engineered specifically for the upward transport of tubes, significantly enhancing system grip and safety.

Specific adaptation to the customer's process

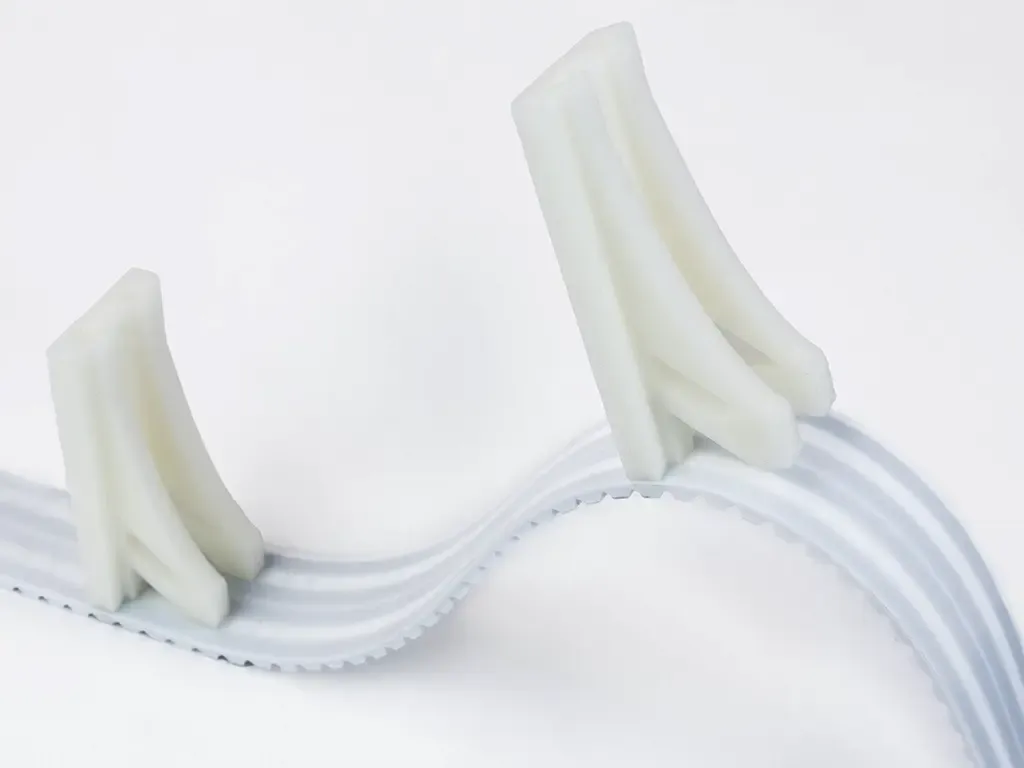

To address the challenge precisely, custom-made cleats were designed to keep tubes in position during ascent, preventing slippage and ensuring load stability.

The design incorporates a curved rear support, specifically engineered to match the tube’s shape and bear its weight without deformation or breakage. This solution improves contact between the tube and the belt, providing a more secure hold and increasing overall system reliability.

Improved safety and productivity

Thanks to this adaptation, it has been possible to optimize the performance of the transport system, reducing incidents caused by unintended movements and improving operational safety. The outcome is increased productivity through minimized downtime and reduced component wear.

Design flexibility as a fundamental principle

This development represents a core principle of the Ydins brand: flexible design to achieve seamless integration in every application. Unlike standardized approaches, Ydins supplies customized belts configured to the demands of the working environment, enabling an effective response to specific technical challenges.

The customization of each component—such as cleats—not only improves functionality, but directly contributes to the efficiency and reliability of the industrial process. In this way, Ydins consolidates its position as a benchmark brand in designing custom-made solutions for conveyor belting.