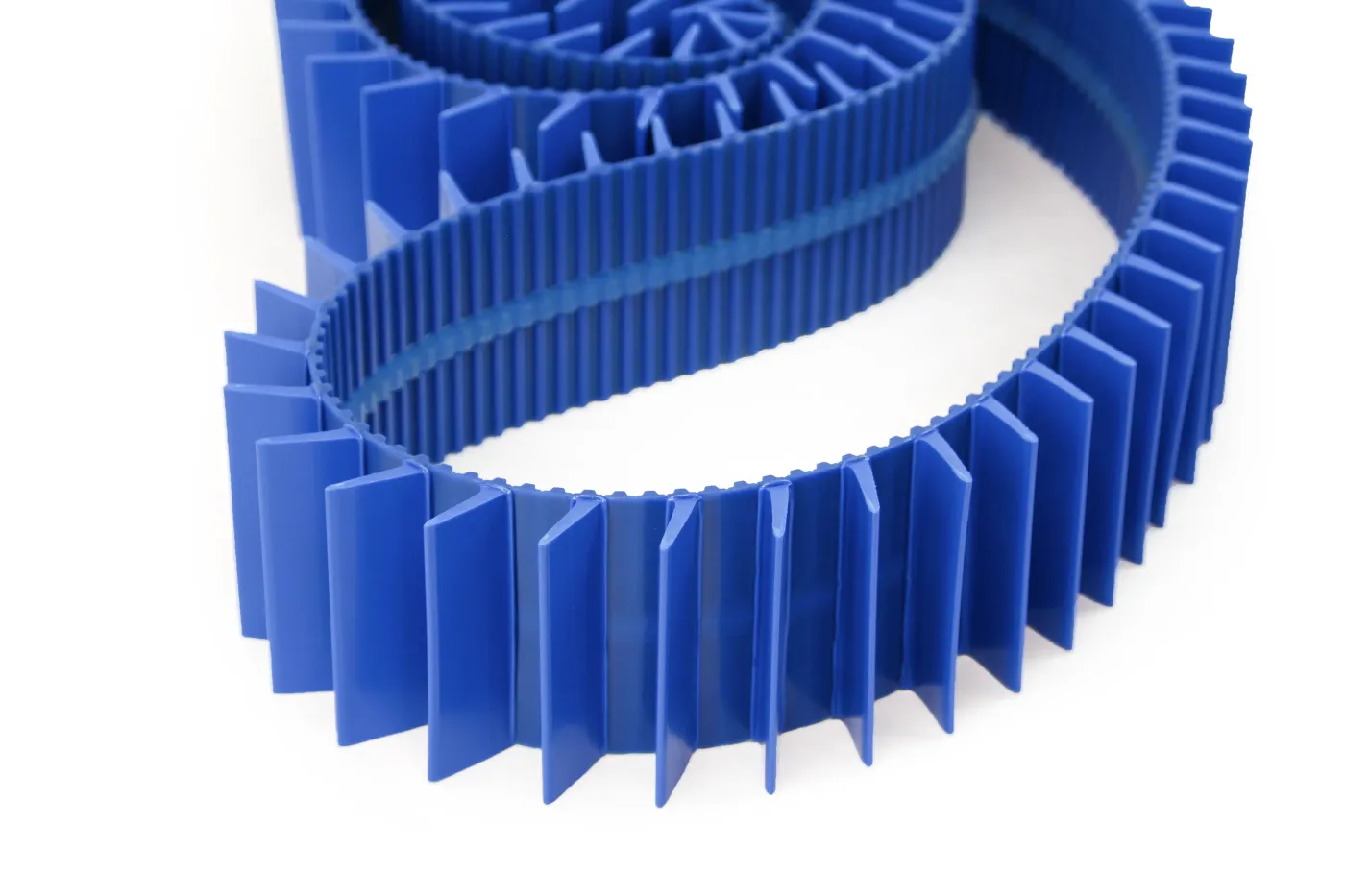

In the food sector, safety, hygiene and traceability are not optional: they are essential requirements. Industrial processes must ensure that each component in contact with the product strictly complies with current regulations. In this context, custom timing belts made of 100% FDA materials, such as those developed under the Ydins brand, represent a reliable and durable solution for production lines that demand the highest level of compliance.

Total adaptation to critical processes

Designed to be integrated into environments with high sanitary demands, these belts are manufactured exclusively with materials certified by the FDA (Food and Drug Administration), ensuring their suitability for applications with direct or indirect contact with food.

The customization is total: the design of the strap is adjusted to the specific needs of the customer, either through specific machining, compatible coatings or the incorporation of plugs and guides. This flexibility allows for the optimization of both system performance and equipment cleaning and inspection.

Key benefits

- High-quality materials with FDA certification

- Chemical and thermal resistance suitable for washing and disinfection processes

- Tailor-made design, adjusted to the work environment and the type of product

- Durability and reliability, even under intensive production conditions

- Tight lead times to minimise downtime

Tailor-made solutions for the food industry

The Ydins brand specializes in the development of timing belts designed specifically for sectors such as food, pharmaceuticals or cosmetics. The combination of high-purity materials and a precise manufacturing process makes it possible to provide an effective response to safety and hygiene challenges, without sacrificing performance.

These belts not only comply with the most demanding regulations, but also adapt to the real conditions of each application, thus guaranteeing efficient and safe integration into any food production line.