Hygiene and safety: pillars of the pharmaceutical and food industries

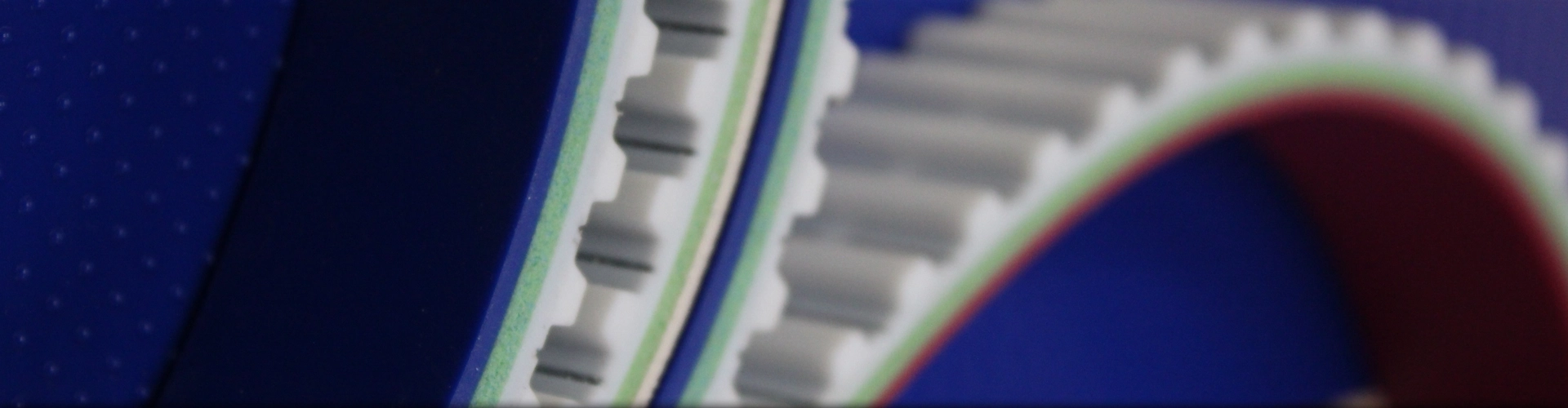

In highly regulated sectors such as pharmaceuticals and food production, process safety and material hygiene are critical factors. International regulations, strict quality controls, and the need to guarantee safe production environments require components that meet the highest technical and sanitary standards.

In this context, the use of FDA-approved materials (U.S. Food and Drug Administration) becomes an essential guarantee. These materials are designed to prevent any risk of migration, contamination, or product alteration, even under demanding working conditions. They offer maximum compatibility with cleaning processes, direct contact with food or pharmaceutical products, and resistance to aggressive chemical agents.

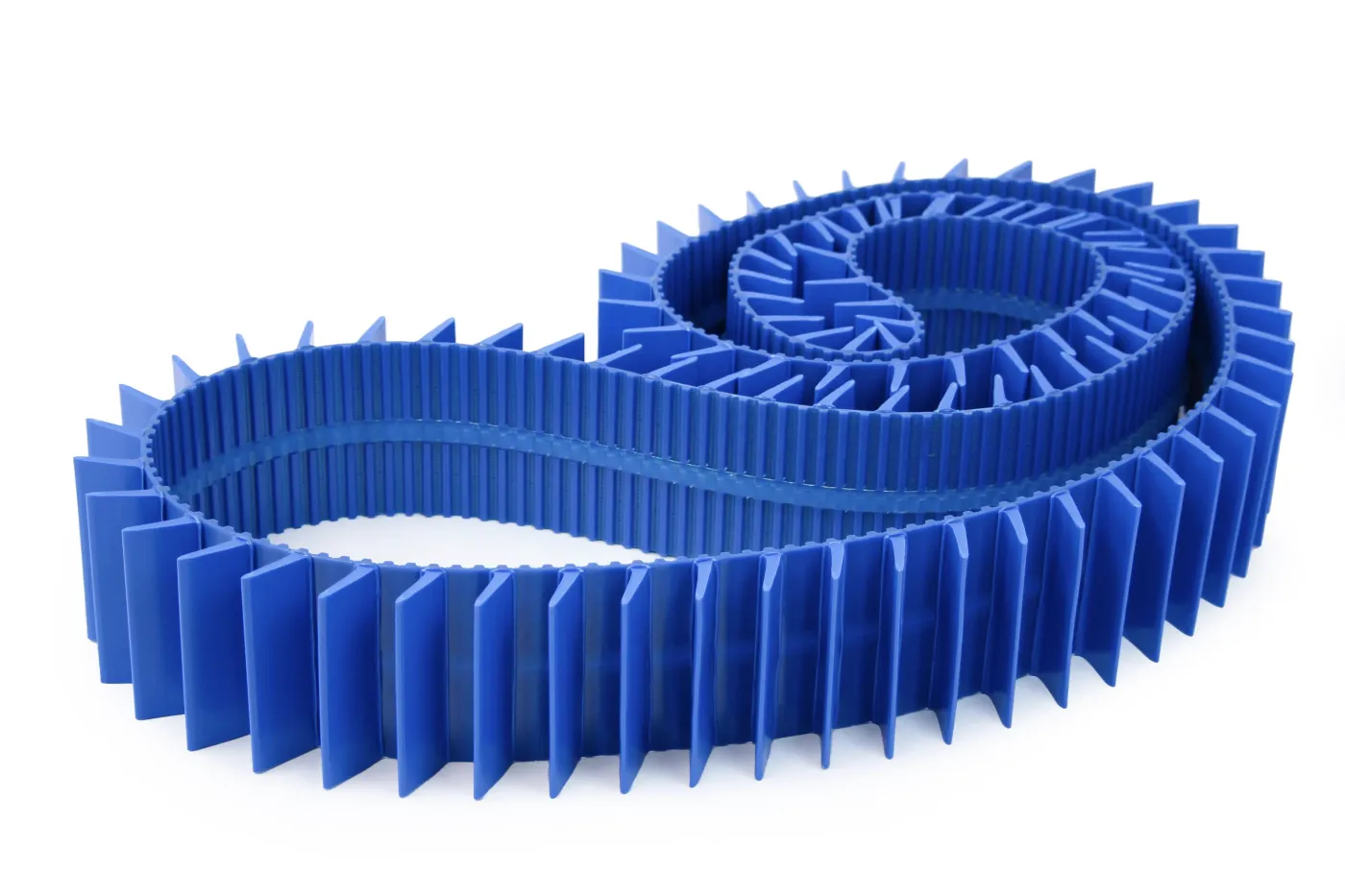

YDINS custom belts: precision, hygiene, and certified quality materials

YDINS designs and manufactures custom timing belts tailored to the specific requirements of the food and pharmaceutical industries, using materials that comply with FDA standards. These custom belts offer the perfect balance between mechanical strength, chemical compatibility, and ease of cleaning, ensuring reliable performance without compromising hygiene standards.

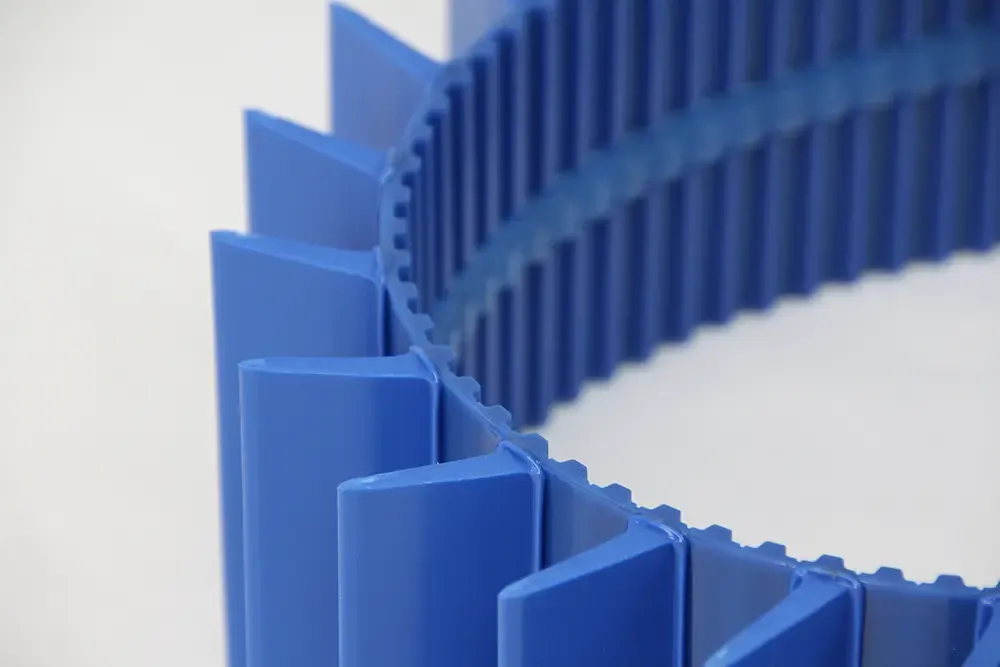

Thanks to their advanced formulation, the materials used by YDINS provide:

• High resistance to abrasion and wear.

• Excellent performance against chemicals and intensive cleaning agents.

• Low moisture absorption and good resistance to hydrolysis.

• Full compliance with standards for clean and strictly controlled environments.

Custom-made solutions without compromising safety

The combination of custom design, FDA-certified materials, and a strong focus on safety makes YDINS a strategic partner for companies that require reliability, control, and traceability in their production processes.

With its custom-made timing belts, YDINS offers technical solutions that not only meet process requirements but also add value in terms of hygiene, regulatory compliance, and operational efficiency.