Ydins custom belts: when a standard belt is not enough

On many production lines, the belt is considered as a standard spare part: it is replaced with an "equivalent" one and the system continues to work. However, when the line demands more speed, greater precision, strict hygiene requirements or the handling of delicate products, the standard belt becomes a clear limit to the process.

In these conditions, micro-stops, misalignments, product drops and constant maintenance appear that reduces the availability of the machine and overall productivity.

Ydins specializes precisely in this scenario: it designs and manufactures custom-made polyurethane timing belts, combining coatings, cleats, machining, inserts and joining systems to adapt to each industrial application and each type of product, from packaging lines to food or pharma processes.

Why a standard belt falls short on demanding lines

A standard belt is defined by dimensions and type of toothing, but it does not take into account the actual product it is transporting or the working environment. In modern packaging, handling or feeding lines, this entails several limitations:

- Inadequate grip depending on the material or type of packaging (plastic, glass, cardboard, film, etc.).

- Loss of product stability, especially in light packaging, unstable formats or inclined transport.

- Premature belt wear and need for frequent replacements, with the associated cost of line downtime.

- Limitation of production speed to avoid incidents, blows and rejections.

- Difficulty in meeting hygiene and safety requirements in regulated sectors such as food and pharmaceuticals, where belt materials must conform to specific standards.

In terms of operation, maintaining standard belts means accepting lower line performance, a higher rejection rate, and a higher than expected total cost of ownership.

What a custom-made Ydins belt provides

Ydins custom belts are designed based on the process and the product, not the standard catalog. The four key axes are:

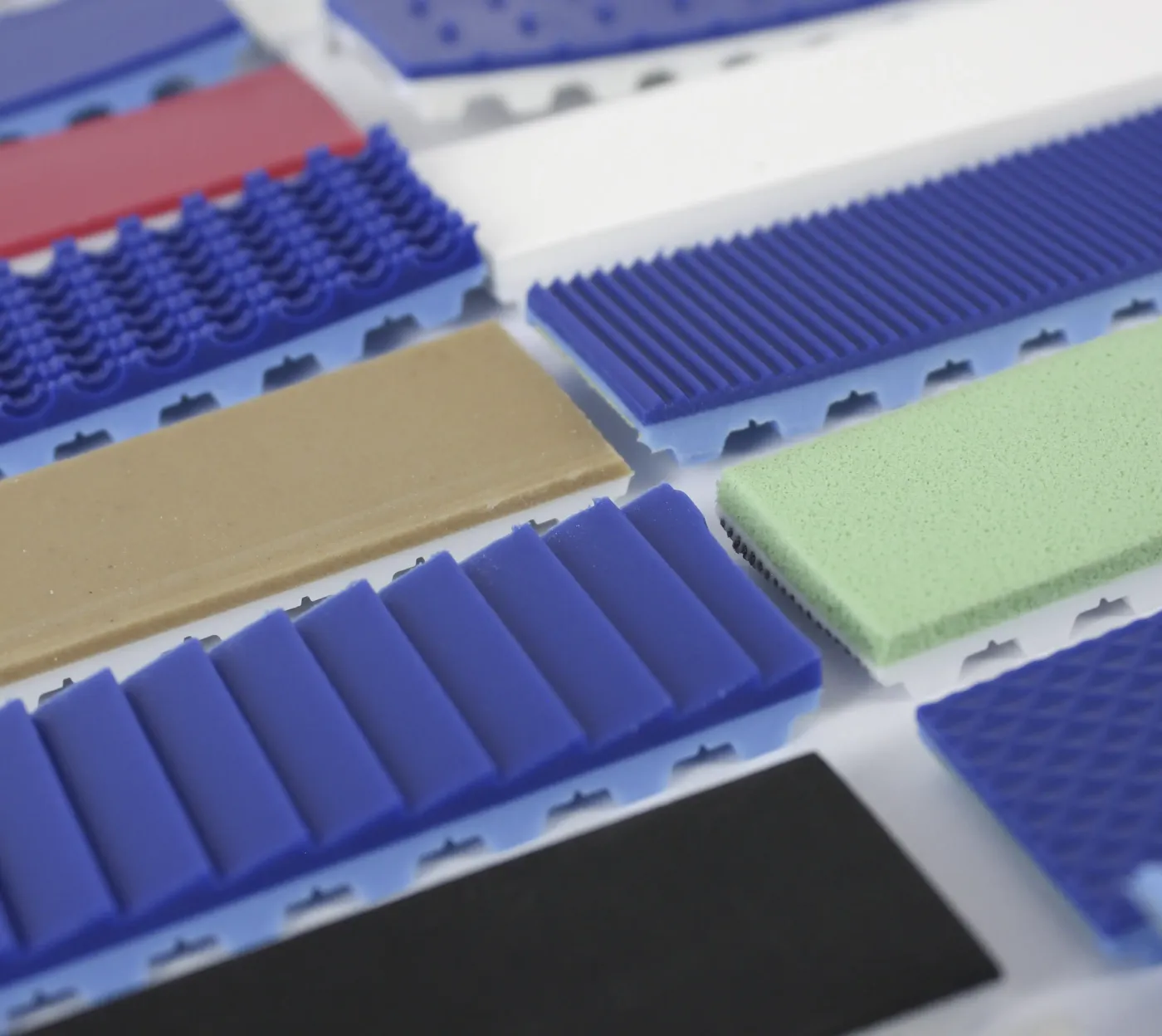

- Belts with specific coatings

To adapt the coefficient of friction, hardness and texture of the belt surface to the type of product and the sector, including configurations suitable for contact with food and environments with frequent cleaning.

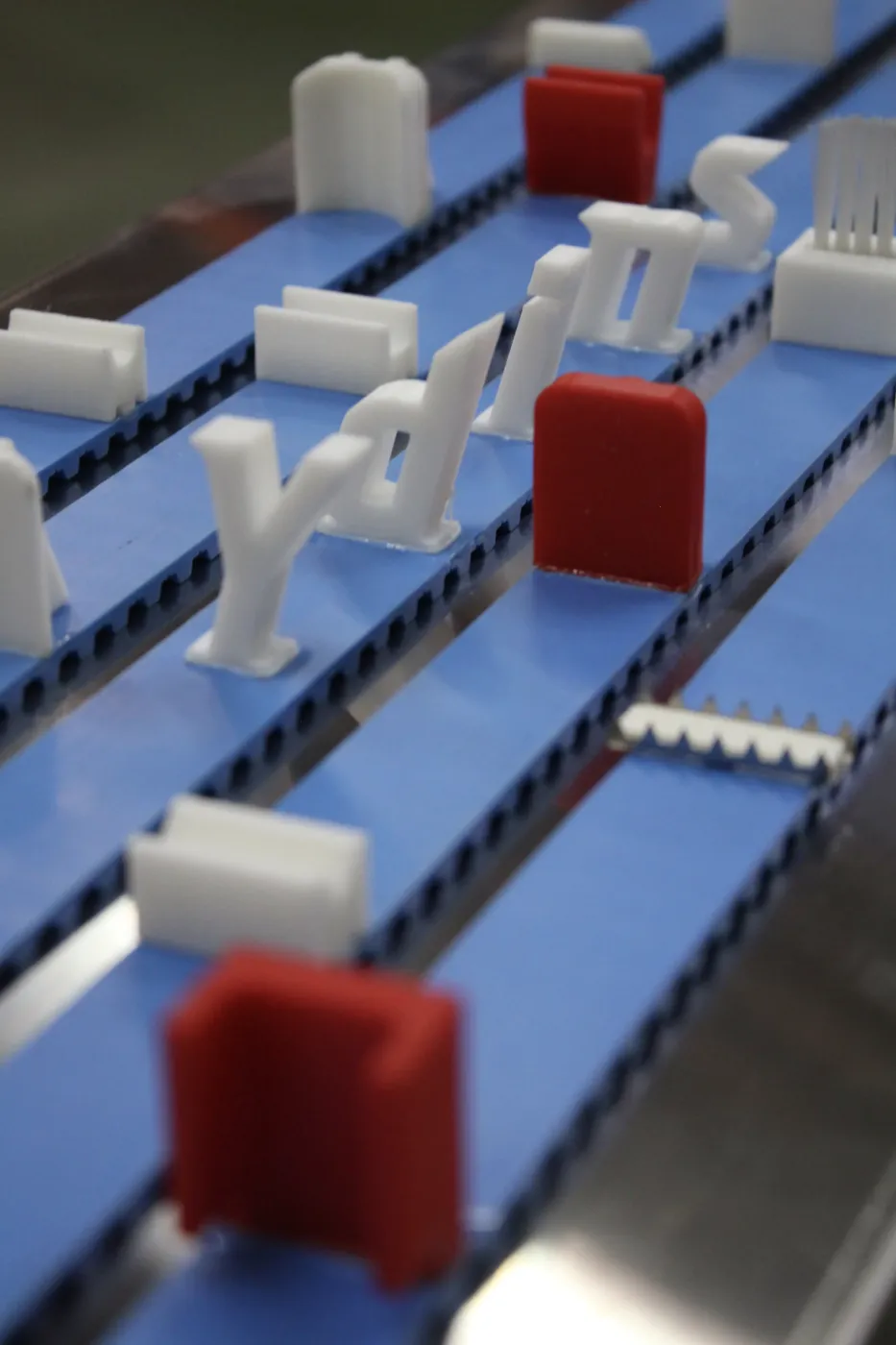

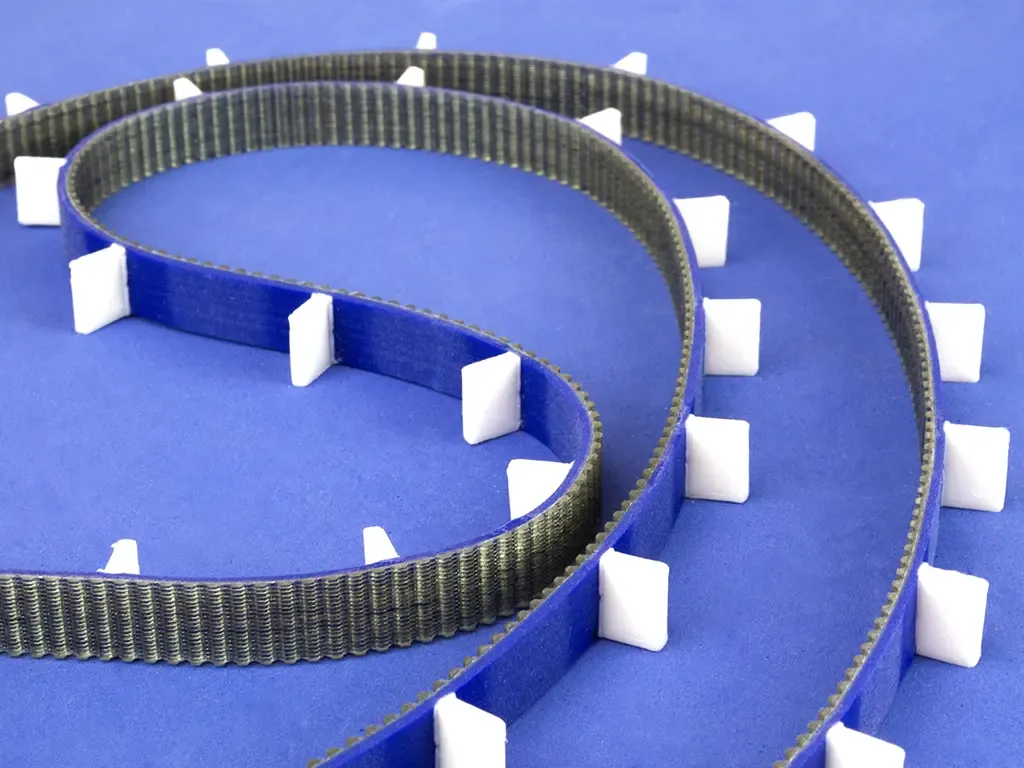

- Custom-made cleat belts

Cleats are designed according to shape, weight and product spacing, which improve grip and positioning. They are especially effective in inclined conveying and unstable parts.

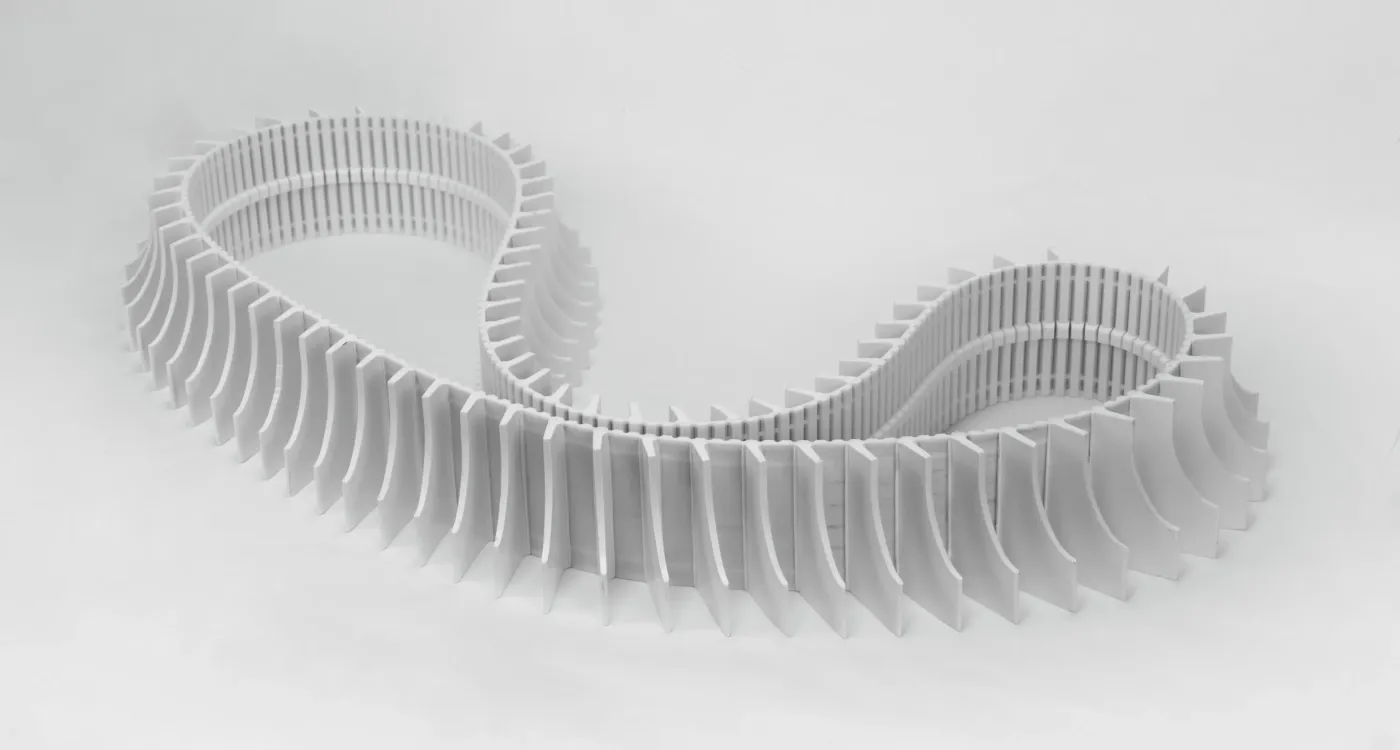

- Machined belts for each machine

They incorporate custom machining (grooves, recesses, guide housings, perforations, etc.) that adjust the belt to the kinematics of the machine, reduce deviations and improve guidance on high-speed lines.

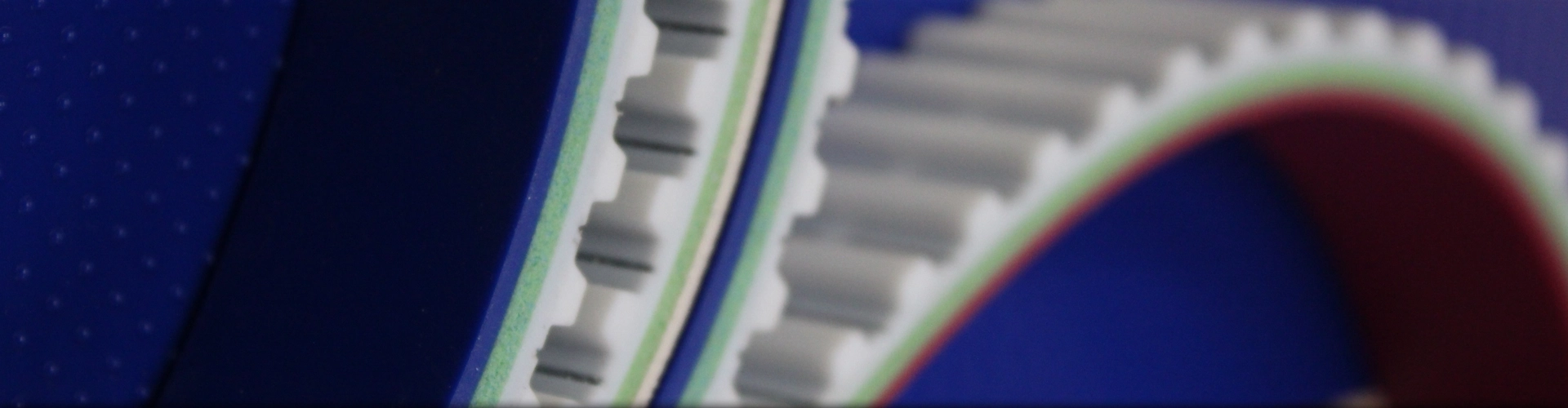

- Belts with inserts and false teeth

They allow you to fix and reconfigure cleats and profiles with precision, maintaining a stable synchronous transmission in applications where product positioning is critical (labeling, dosing, packaging, vision systems, etc.).

- Belts with built-in customization

By combining coatings, cleats, machining, inserts and false teeth on the same belt, Ydins more precisely adjusts the belt-product-process interaction, improving line performance and providing flexibility in the event of format or product changes.

From standard replacement to strategic element of the process

When a plant wants to increase production speed, reduce downtime and ensure product quality, the belt is no longer a simple standard spare part and becomes a strategic element of the process.

Ydins' bespoke polyurethane timing belts allow for stability, speed and reliability where the standard belt becomes a bottleneck. Rather than tailoring the line to a generic component, the belt design is tailored to each facility's product, machine, and regulatory environment.

In this way, the belt goes from being a recurring cost to becoming a technical asset that directly contributes to improving machine availability, final product quality and total process cost.

If you detect these problems in your production lines, contact Ydins and our technical team will analyze your application to define the polyurethane timing belt that best optimizes the performance and stability of your process.