In the world of packaging, staying competitive hinges on efficiency and precision. Belts sit at the core of these operations, guaranteeing smooth, safe, and continuous product conveyance. YDINS responds to the sector’s needs with custom belts and advanced machining that elevate throughput and extend durability.

The Importance of Custom Belts in Packaging

Packaging and wrapping demand meticulous control to handle products reliably and at speed. Custom belts adapt each component to the target equipment—filling machines, labeling machines, or vertical bagging machines—cutting wear, optimising energy consumption, and shortening stoppages. Bespoke belts also secure full compatibility with sensors, guiding systems, and other essential elements in the line.

The Role of Special Belts in Vertical Bagging Machines

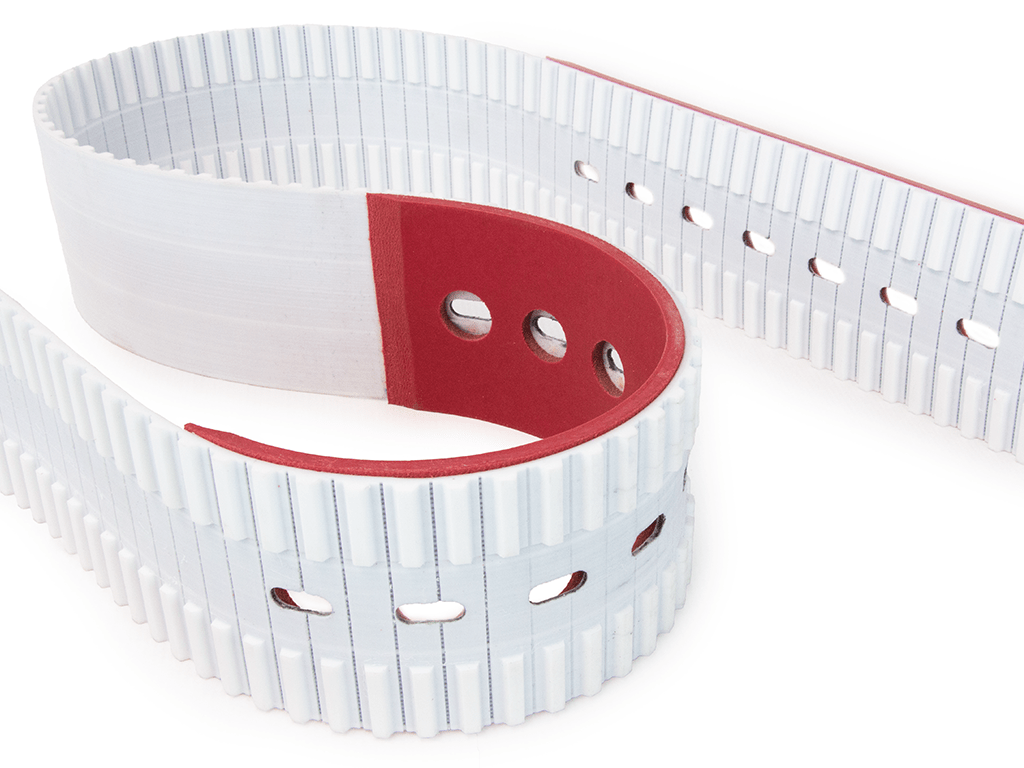

Special machined belts are central to modern packaging, enhancing airflow, accuracy, and versatility. They shine in vacuum-assisted applications, where suction stabilises items for safe transport or processing. Vertical bagging machines benefit especially from these customised belts: they refine material handling and increase overall bagging efficiency. Their custom perforation patterns enable effortless integration across different packaging configurations.

Special Coatings

YDINS provides a wide portfolio of coatings for varied operating conditions—from anti-slip surfaces that guarantee firm grip to wear-resistant finishes that maximise belt service life in demanding environments. In vertical bagging machines, these coatings are key to maintaining consistent, repeatable performance.

Why Choose YDINS

YDINS combines deep expertise, a personalised approach, and robust technological capabilities to deliver solutions precisely aligned with each client’s requirements.

YDINS custom belts are a sound investment in efficiency and quality for packaging and wrapping lines. With extensive machining options and a strong commitment to excellence, YDINS is the ideal partner to take your production to the next level.